iPhone Logic Board Repair (2016)

4. Defects

In the former chapters i have told how a the logic board works, the functions of its main components and the tools needed for repair. In this chapter I will move on discussing the most common reasons for damage, and the most common defects resulting from that damage.

The kind of defects can be numerous. From a less dramatic defect like a not working compass, to more devastating defects, like a shorted processor unit. The most common forms of damage are: Water damage, repair damage, a fall, a wrong charger and bending.

4.1. Water damage

When a powered on logic board gets wet the water can act as a bridge conducting current to places where it shouldn’t go. It creates heat and components can get burnt. This way water damage can cause permanent shorts to GND. The iPhone can lose functions, or decide to not turn on at all.

A water damaged iPhone not powering on mostly happens when one of the two most important lines: BATT_VCC or VVC_MAIN, is affected. When able to locate and relieve a short on 1 of these lines the iPhone normally will return back functioning.

There are different methods for detecting a short to GND. Abnormal power usage can be seen using a DC power supply and is indicative of a short. A short also creates heat. This can be felt with your lips.

When a line is shorted the capacitors on that line will beep on both sides. But most of the time there is only one component the culprit. Your task it to find that “sucker”.

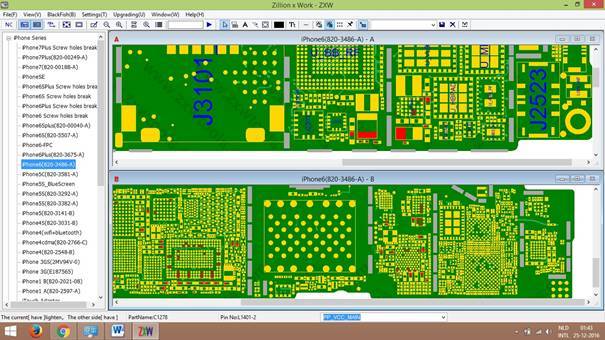

For this you power the shorted line with a DCPS. The voltage must match the normal voltage of the shorted line. And with things like freeze spray and your lips you try to find and replace the shorted component. The ZWX-tool shows you which components are on a the shorted line.

Liquids can also cause residue and corrosion on the board. Proper clearing is mandatory. For cleaning: alcohol and a brush can be used. Water damaged iPhone can have invisible damage and can there for be potentially be unstable. Many repairs shops do water damage repair for data recovery only.

4.2. Repair damage

Repair damage can happen during a “normal” iPhone repair like a lcd or battery replacement. This can cause defects like no more backlight or no boot at all. Repair damage can be detected using a microscope. When uncertain if a small component is effected one can try pinching it a little with a needle to see if it moves or test it with a multimeter. The ZXW tool can help you determine which functions are affected. video

4.3. Falling

When a iPhone drops hard, changes are that a IC loses full contact with the board (cold solder), or that for example a glass IC breaks. These kind of problems can be harder to detect. If possible you can try get into DFU mode and see what error pops ups. The error code can indicate where the problem is. Many times a reflow of the effected IC helps out. A reflow is heating a IC until the solder under it melts. When there is epoxy under a IC then a replacement is a saver option. replacement. Another method is pressing the suspected IC while booting. Subspecies IC’s are the Power Management IC (PMIC), the NAND Flash IC and the Processor IC.

4.4. Wrong charger

Using a non-official iPhone charger can damage the charge IC. In that case the Iphone wont charge or wont boot at all. It can also show with other symptoms like the message: "The accessory may not be certified” when inserting the charge cable. The only remedy is replacing this IC.

4.5. Bending

Bending can also be a cause of cold solder under IC’s. The IPhone 6 and 6 plus are notorious for this problem. The infamous “ Touch disease” .The reason for this seems to be a design flaw. The housing is prone to bending. And no epoxy is used under the two Touch IC’S. Replacement is of the IC’s the only remedy.

4.6. Long screw damage

As told you before: current through so called “traces” inside and on top of the logic board. And these traces follow a path and connect the components. When a trace or a component gets damaged it is possible that the flow in that line is blocked. The blockage needs to be removed or the trace reconnected.

A special case of trace damages is the so-called “long screw damage”. This can happen when a long screw is used in a small screw bracket. The screw then can pierce some traces. As a result all kind of malfunctions can occur. These repairs are high skill. The ZXW tool shows which lines are involved.

4.7 The most common repairs

As a result of the damages described in this chapter the 4 of the most common repairs are:

1. Defected touchscreen

2. Defected backlight

3. Defected charging

4. No power

All materials on the site are licensed Creative Commons Attribution-Sharealike 3.0 Unported CC BY-SA 3.0 & GNU Free Documentation License (GFDL)

If you are the copyright holder of any material contained on our site and intend to remove it, please contact our site administrator for approval.

© 2016-2025 All site design rights belong to S.Y.A.