Idiot's Guides: 3D Printing (2015)

PART 2

All About the Hardware

CHAPTER 10

Choosing a 3D Printer

In This Chapter

![]()

· Open vs. closed source

· Whether getting an assembled printer, printer kit, or DIY printer is right for you

· What are your printing needs?

· Designs beyond Cartesian printers

Now that you know the different parts that make up a 3D printer, it’s time to think about what type of 3D printer is right for you. Deciding on what 3D printer to purchase can be both overwhelming and exciting. The increasingly abundant number of manufacturers and models on the market are sure to make anyone dizzy. Do you need a 1.75mm or 3mm hot end? Is one company better than another? Should you care about whether or not it’s open source?

There are a plethora of options and factors to think about, but if you can make a few early decisions, you’ll gain a lot of focus in your search. Most people already have an idea of what they want and expect from their printer, so it’s just a matter of consciously deciding what’s important to you.

In this chapter, I take you through some things you should consider when purchasing a 3D printer. Once you’ve narrowed your list down to a few models, the choice will become a simple matter of picking which has the best reviews and price.

Open or Closed?

Do you care if the printer is open source? For many people, this is the most important factor in their purchase. For others, it’s largely irrelevant. The consumer 3D printer market is divided roughly 50/50 between open-source and closed-source printers, so choosing which kind you want initially can cut down your options by half.

What Does It Mean to Be Open Source?

Let me first explain what I mean by “open source.” If you recall from Chapter 2, the basic open-source concept is simple: intellectual property is shared freely so others can modify it, use it, and share it themselves. This is in direct opposition to the practice of controlling intellectual property via patents and copyrights (otherwise known as closed source). Open-source data can still be patented and copyrighted, but to be considered open source, it has to be licensed to allow sharing.

![]()

DEFINITION

Intellectual property is any idea that is legally protected. Providing legal protection for intangible things like ideas is a complicated matter, and the laws vary from country to country. But in the United States, intellectual property like inventions, music, copywriting, patents, and so on are legally protected property.

In the early days of the internet, many people believed that patents and copyrights of technology, especially software, were counterproductive and inhibited progress. Both individuals and corporations pushed the idea you could share your ideas while making a profit and fueling innovation.

In 1985, the Free Software Foundation (FSF) was created to support and promote this movement. At the time, the primary goal was to ensure people’s freedom to use their hardware as they pleased without being restricted by proprietary software. Over time, this ideology evolved to encompass a broader idea of open software. Then, in 1998, the Open Software Initiative (OSI) was created with very similar goals in mind. Together, these organizations (and others) have helped to create the many free and open software options we enjoy today.

But it doesn’t stop with just the software. A more recent trend is the open hardware movement. The ideals are similar, but instead of developers making their source code public, engineers are making their designs public. In the same way you can download Linux source code under the GNU License created by FSF, you can download blueprints and design files from open hardware companies. The entire RepRap project is based on that idea and has been completely open source from the very beginning. In fact, many of the 3D printers on the market today are RepRap designs or derivatives.

Additionally, other manufacturers have developed their own designs independently of the RepRap project but also have made them open source. For example, Aleph Objects makes the only 3D printer to carry a hardware certification from the FSF. That printer, the Lulzbot, is the printer featured in the photos throughout this book. The kind of information most companies keep under lock and key, such as design files and documentation, is made freely available by Aleph Objects.

The Lulzbot TAZ 4 is the only 3D printer available that is certified by the FSF.

Many other manufacturers stay true to the open-source ideology as well. Like Aleph Objects, they make their design and engineering documents available to the public. The key is they share their designs, make their printers compatible with open-source software, and allow customers to use their printers however they wish.

Why It Might Matter to You

You now know what it means to be open source, but why should it matter to you? What difference will it make, practically speaking?

The biggest argument for the purchase of an open-source printer is freedom. You’ll have the freedom to use whatever software you please and to modify your printer however you like. You won’t be restricted in what you can and can’t print, where your files come from, or how you use them. If you decide you don’t like the software recommended by the manufacturer, you can just switch to another program. You won’t be required to use proprietary filament cartridges or be restricted to approved accessories.

![]()

HOT TIP

Many 3D printers with closed-source hardware are still capable of using open-source software for slicing and control. Open-source software may even be recommended by the manufacturer. When you’re looking at printers, be sure to check which software the manufacturer recommends and whether you’re free to use other software.

With all of that said, there are many great 3D printers on the market that are not open source. You may decide the printer for you is closed source. There is absolutely nothing wrong with going that direction. After all, the vast majority of things we buy on a day-to-day basis aren’t open source. Most completely closed-source manufacturers strive to make their systems seamless and easy to use, and you may find that you prefer one of those systems. But be sure to consider the decision carefully, since closed source is more restricted.

Assembled, Kit, or DIY?

The next factor to consider is how you want to receive your printer from the manufacturer, or if you want to skip the manufacturer altogether and build your own 3D printer. This choice shouldn’t be taken lightly, so I’m going to explain the advantages and disadvantages of each option.

Assembled 3D Printers

If you are unsure what you want to do, this is absolutely the safest choice. Purchasing your printer already assembled from the factory is the easiest and most reliable way to start printing. You won’t have to worry about assembly; you can just unbox it, do a few setup steps, and be printing your first model in an hour or two. And most assembled printers will come with a warranty of some kind in case anything goes wrong, which may not be the case with the other options. It’s also likely that you’ll be able to receive some technical support if you run into any problems.

Cost is the biggest downside here. Someone had to be paid to assemble the printer, and that results in a higher price. Shipping costs may be higher as well, as the box will usually be bigger than that of an unassembled printer. And, although it’s assembled, you’ll probably still need to do a little bit of adjustment to get it actually printing.

3D Printer Kits

Kits are a great way to save some money and an opportunity to learn about your printer as you’re building. The knowledge and experience you gain building the printer can help tremendously in the future with troubleshooting and modifications.

Generally, a kit will include all of the parts and hardware you need to build your own printer. It should come with the frame pieces, fasteners, electronics, motors, and anything else you’ll need to build a working 3D printer. Most kits on the market today are based on RepRap designs, but there are some that were independently designed. Like with an assembled printer, your decision should be based on your needs, but you’ll also need to take into account build time and difficulty.

What it takes to build a kit can vary quite a lot. Some kits come partially assembled and just require that you fit the pieces together. Other kits will require that you assemble each and every part on your own, so you may need special skills (like the ability to solder). You may also have the option of ordering a partial kit that includes everything except 3D-printed parts, which can be a good way to save some money if you know someone who can print those parts for you.

The downsides to kits are that they can be very time consuming to assemble, they require tools, and assembly can be difficult. Therefore, make sure you’re confident in your ability to assemble the printer before you purchase it.

Building a DIY 3D Printer

Another option is to build your own do-it-yourself (DIY) printer using designs published by individuals or open-source companies. Most of these designs are based on the RepRap project, and many are tried and true. Building your own printer can save you a significant amount of money and gives you the opportunity to modify the design to build the exact printer you want. (See Appendix B for some helpful links on how to do this.)

My DIY 3D printer, based on the open-source TAZ design.

The downside, of course, is that it’s completely up to you to source all of the parts and put them together. This is a very difficult task, and I wouldn’t recommend it for your first printer. But for a second printer, or for the adventurous, it can be very rewarding and a great learning experience.

Determining Your Needs

At this point, your choices should already be considerably narrowed, and hopefully a few manufacturers and models are starting to stand out. When looking at these remaining models, consider what your needs are and what you need your printer to do for you. What kind of models will you be printing? What will their use be? What kind of filament will you use? What should everything cost? The following are a few specific things you’ll want to pay attention to.

![]()

HOT TIP

3D printer manufacturers will sometimes publish specifications in inches, millimeters, or both, so you may have to do some unit conversions when comparing printers. However, metric units (millimeters specifically) are generally the standard when exporting and importing STL files and when configuring parameters in software and firmware. Be sure to check what units are used and required when working with different 3D printers.

Print Volume

Print volume is the specification that tells you how large a model (or models) you can print. In most cases, this will be rectangular, and is calculated by multiplying the print width, length, and height. However, for some printers (particularly Delta-style printers), the print volume is cylindrical and calculated by multiplying pi by radius squared and height (πr2h). If you do choose a Delta printer, be sure the circular base is suitable for your needs.

While looking at the print volume is certainly a useful way of comparing printers, it doesn’t quite tell the whole story. Two printers with the same print volume could have vastly different dimensions that might affect your decision. For example, Printer A has print dimensions of 8×8×8 inches, while Printer B has print dimensions of 16×16×2 inches. Both printers will have a print volume of 512 cubic inches, but how useful would a printer be that could only print a model 2 inches tall, as in the case of Printer B?

For that reason, it’s a good idea to look at the actual dimensions. What is the print size in the X direction? How about Y and Z? Determine the largest size you’ll be likely to print, and make sure the printers you’re considering can handle it.

You may be tempted to just buy the printer with the largest print volume, just in case. But keep in mind that both cost and print time increase with print volume. Therefore, there is little sense in paying a lot of money for a big print volume you won’t actually use. Plus, print time increases exponentially with size (you can thank the square-cube law for that).

![]()

DEFINITION

The square-cube law is a scientific principle that describes the mathematical relationship between size, surface area, and volume. Its relevance to 3D printing is the way that volume (and therefore print time) increases exponentially with size. For example, a cube 10mm to a side has a volume of 1,000mm3. Doubling the dimensions of the cube to 20mm to a side results in a volume of 8,000mm3. Because the larger cube is 8 times the volume, it will take 8 times longer to print than the smaller cube.

Print Resolution

Print resolution is essentially a measure of the potential quality of your printed models. Smaller is better here, similar to how smaller pixels result in better image quality on your computer monitor. A smaller resolution means you can print finer details, and the overall surface finish of the model will be smoother. But determining the print resolution that a printer is capable of can actually be a tricky task. There is currently no practical way of specifying the actual effective print resolution of a 3D printer in the real world.

Theoretically speaking, print resolution should be the result of two factors: nozzle size and movement precision. The nozzle size determines how fine the filament thread being ejected from the hot end is. Because nozzles are replaceable, this isn’t something you should be too concerned with—you can always change the nozzle to one with a smaller opening. However, movement precision can’t be altered without significant modification to the printer’s hardware, making it an important consideration.

This can be calculated with the “steps per mm” information, which should be provided by the manufacturer for use when configuring your slicer and firmware. For instance, if your X axis is 200 steps per mm, your movement precision on that axis is 0.005mm (1mm divided by 200). But no matter how precise the movement is, the nozzle size will restrict how detailed your prints can be. If the nozzle is too big, it won’t be able to print very fine detail. It’s analogous to trying to write small text with a marker—the marker is just too big to write fine details.

There are other concerns that factor into the resolution of a 3D printer though. Just something that seems relatively minor, like flex in the printer’s frame, can reduce the effective resolution of the printer. This means that the resolution specified by the manufacturer might only be achievable at slow speeds under the best circumstances.

Filament

There are many filament materials on the market, and the choices are rapidly increasing. Different 3D printers are capable of utilizing different filament materials, and it’s worth paying attention to this when choosing a printer.

If you remember from Chapter 7, the two most common filament materials in use today are PLA and ABS. PLA is widely considered to yield higher-quality prints, while ABS parts are generally stronger and more durable. ABS is also easier to work with postprint (for sanding, drilling holes, and so on). Virtually all FFF 3D printers are able to print with PLA, while ABS requires a heated bed to print successfully. If you purchase a printer with a heated bed, you’ll be able to print the two most popular materials. However, 3D printers that don’t come with a heated bed included will often have that as an accessory specifically to allow you to print ABS.

Other more exotic materials may require specialized hardware. For example, if you’re interested in printing flexible filament, a printer with a Bowden extruder will not work. The filament simply bends too much in the feed tube and won’t be able to feed reliably. So you should only consider direct feed extruder types if you want to print flexible filament.

![]()

DEFINITION

Flexible filament is an umbrella term for any filament material that is flexible, rubbery, and squishy. This can be used as an alternative to the hard and rigid plastic that is more commonly used for 3D printing. The exact composition differs depending on the manufacturer, but the resulting material is fairly similar with all of them.

Other materials, like polycarbonate, require special hardware to print. In Chapter 18, I’ll go into a lot more depth about what other materials are available and what kind of hardware you’ll need to use them. It’s worth skipping ahead to that chapter if you’re curious about some of the more unique materials and want to know what you’ll need to print with them.

Besides filament material, you also need to decide on what filament size you’d like to be able to use. Currently, 3D printer filament comes in two sizes: 1.75mm and 3mm. Originally, most filament came in 3mm. As nozzle sizes decreased, however, it took more force to push 3mm filament through the nozzle. For that reason, 1.75mm has become the more popular choice, with a wide range of manufacturers and color options. However, flexible filaments generally feed more reliably in 3mm because the thickness increases the stiffness, making it less likely to bend and jam. Some filament manufacturers only sell their flexible filaments in 3mm due to that.

With all of that said, both 1.75mm and 3mm 3D printers will have a very wide selection of filament to choose from. Don’t put too much weight on this factor; rather, first find a 3D printer you like. If that printer has an option of 1.75mm or 3mm, decide on a size based on your needs.

Prices

Until just a few years ago, the high cost of 3D printers meant that usually only corporations could afford to purchase them for prototyping purposes. Luckily for both hobbyists and small companies, 3D printer prices have recently dropped dramatically. In a very short amount of time, the least expensive printers have gone from being tens of thousands of dollars to just a few hundred. Even better, a current midrange consumer printer is capable of rivaling the quality and print volume of professional 3D printers from only a few years ago.

So what can you expect to pay for a consumer 3D printer for personal use? Obviously, price will vary depending on size and features, but proven and well-reviewed printers range from about $400 to $3,000. At the bottom end, you have very basic printers with small print volumes that are often constructed out of inexpensive materials like wood. As prices rise, print volume generally increases, more features are added, and frames are made of higher-quality materials. At the high end of the consumer market, you have 3D printers that would even be suitable for an engineering or prototyping environment.

Simply put, this is an exciting time to purchase a 3D printer! Prices are low enough that it’s realistic for an average person to purchase one for home use. The market is very healthy, and there are options out there to suit a variety ofneeds.

![]()

HOT TIP

When thinking about cost, remember to keep room in your budget for tools, accessories, and filament as well. Filament prices range from about $25 to $50 per kilogram for ABS and PLA, and a kilogram should be enough for you to get started with. It’s also a good idea to have a basic set of hand tools available—such as wrenches, pliers, and screwdrivers—along with various glues and tapes.

Printers with Unusual Designs

For the purposes of simplifying this guide, I’ve been talking primarily about Cartesian 3D printers that use FFF technology for printing. Cartesian printers are set up with a rectangular build area with movement in three axes, and are by far the most common type of printer on the market (see Chapter 5).

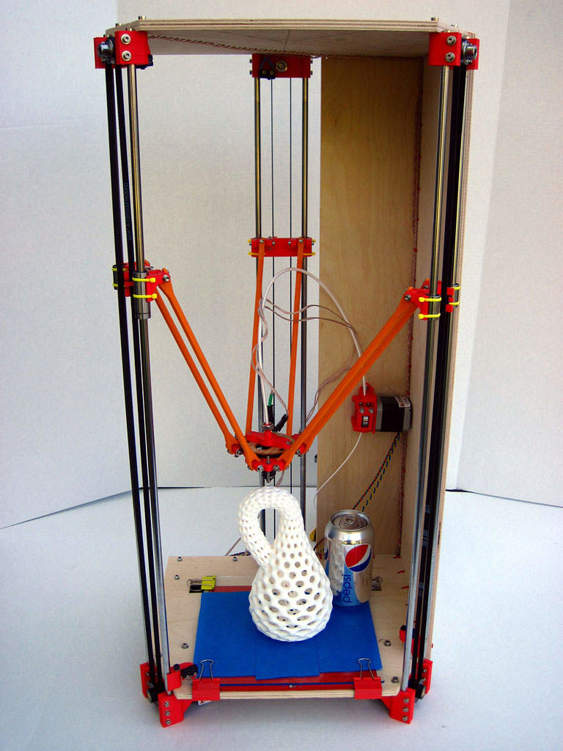

However, there are other kinds of printers out there which you might come across. One type that has gained a lot of popularity recently is the Delta-style 3D printer. These use a unique method of movement where the build platform is stationary and the hot end is moved on three arms attached to vertical rails. Delta printers are advantageous because they’re capable of printing at higher speeds. However, being a newer design, there is less information and support available. They also have a circular build platform as a result of their unique geometry, which might not suit your needs.

This is a Delta-style Rostock 3D printer, a RepRap design.

Another design that has recently started to enter the consumer market is digital light processing (DLP). Traditionally, these types of 3D printers were expensive and the technology was only used in professional printers. But prices have dropped low enough that they could be worth considering. DLP printers work by shining light onto a vat of UV-curable resin. As the light hits the resin, it cures and hardens, eventually resulting in a plastic part.

DLP 3D printers are capable of producing high-quality parts with very fine detail, but they also have significant drawbacks that make them unattractive options outside of specialized uses. The resin used is much more expensive (per kilogram) than traditional filament, and the selection is much smaller. Plus, color and material options are only a small fraction of what is available to FFF printers. They’re also unable to print hollow parts, as the uncured resin is left inside the part.

In addition to Delta and DLP 3D printers, there are a number of other more exotic designs out there. However, they are all fairly experimental at this point and probably wouldn’t be a good choice for your first 3D printer. In fact, it’s probably best to stick to a Cartesian printer unless you have a specific need for one of the other types. The popularity of Cartesian printers ensures that you’ll have access to a wealth of information and support, as well as a widerange of choices.

The Least You Need to Know

· Make sure you consider your present and future needs when determining what printer to buy.

· Choosing an open-source 3D printer provides benefits for support, flexibility, and modifications.

· Prices have dropped dramatically in recent years, but 3D printers are still a hefty investment. Kits offer savings and an opportunity to learn the ins and outs of your printer.

· If you’re new to 3D printers, it’s best to stick with the popular Cartesian printer. That way, you’ll have access to plenty of support and information.