Knowledge-based Configuration: From Research to Business Cases, FIRST EDITION (2014)

Part IV. Case Studies

Chapter 17. Tacton: Use of Tacton Configurator at FLSmidth

Klas Orsvärna and Morten H. Bennickb, aTacton, Stockholm, Sweden, bFLSmidth, Copenhagen, Denmark

Abstract

FLSmidth is a leading vendor of equipment for cement plants, with a long experience of using software to support product configuration in making proposals as well as in order processing. This paper describes their experience implementing Tacton Configurator, integrated with various other systems such as SolidWorks 3D CAD, SmartPlant 3D, Mathcad, and legacy ERP. Integration was found to be a critical success factor. Other critical success factors were the use of a powerful constraint-solver engine as well as product experts dedicated to configuration modeling. We describe the identified business benefits such as improved productivity, shorter lead times, standardization, higher quality, and increased market share.

Keywords

Knowledge-based Configuration; Tacton; Application Scenario; Industry

Acknowledgments

Kristin Lund provided valuable assistance in gathering data and editing. SolidWorks is a trademark of Dassault Systèmes. SmartPlant is a trademark of Intergraph. Matchcad is a trademark of Mathsoft.

17.1 Introduction

FLSmidth is the world’s leading supplier of complete cement plants, as well as a leading supplier of plants and equipment for minerals processing. We begin by describing the company and its business. We briefly describe their previous experiences of using configurators and why Tacton Configurator was chosen to replace them. One critical success factor was the use of a powerful constraint-solver, thus, we describe the advantages and some of the important requirements of such a configurator. The company has appointed a dedicated team of engineers to take care of most of the configuration modeling. Integrations to related business and engineering systems are important for reaching the full benefits of configuration systems (Tiihonen and Soininen, 1997). We describe the integrations of FLSmidth at a high level. Finally, we describe the identified business benefits and draw some conclusions.

17.2 FLSmidth Company Introduction

Headquartered in Copenhagen, Denmark, FLSmidth employs approximately 14.000 people around the world, most of whom are engineers. Although most of the products are designed by FLSmidth, most of its manufacturing is outsourced to suppliers.

FLSmidth strives continually to improve efficiency and quality. For that reason, the company has been at the forefront of industrial equipment vendors in using software to support engineering and handling of product data. FLSmidth has acquired a lot of companies that supply related equipment, which exemplifies a strong trend in the industrial equipment sector; to consolidate and become a one-source supplier of a complete end-to-end manufacturing process solution. This also means that staff involved in the process from customer inquiry to order fulfillment must handle a very wide range of products, which makes the use of product configuration tools essential for generating quotations—calculating the cost and price, producing proposal documentation that describes the proposed solution, and processing orders to systems for manufacturing execution and supply chain.

17.3 Cement Plants

The size of a complete cement plant is gigantic, in the order of one kilometer long, and the biggest product can be over a hundred meters high (Figure 17.1). The input to a cement production plant is raw materials such as limestone and clay. The process of producing thousands of tons of cement per day from this input consists of numerous steps including crushing, grinding, mixing, heating, and cooling. Each step is performed by one or several configurable products. Between and within all these processes, the materials are transported via various types of conveyors, mechanical as well as pneumatic. In total, a cement plant consists of hundreds of configurable products, most of them designed by FLSmidth. Each product is highly configurable in its own right, many of them consisting of thousands of components. The configurator software must be able to configure the individual products one by one, but also to configure the whole system of products. The equipment configuration depends heavily on the specific properties of the raw materials at hand at the customer site, choice of different techniques, capacity requirements, available space, and so on. In all products, reducing pollution and energy consumption is very important. The configurator must therefore be able to integrate with sizing calculations to take those application requirements into account. Although layout decisions are made by the plant designer, by using the plant design software, the configurator must be able to parameterize product configurations so that components can be customized automatically in terms of dimensions and positions to comply with the spatial requirements driven by the layout.

FIGURE 17.1 A cement plant supplied by FLSmidth.

The configuration requirements of FLSmidth are typical for industrial equipment; a seemingly standardized process requires a vast range of variation due to differences in the capacity, properties of the input and output, efficiency requirements, automation, environment, safety, reliability, available space, and so on. The combinatorics result in billions of potential combinations even in a single product. It is relevant to compare with the configuration requirements of consumer products, since those are much more well known. Products for individual consumers are typically standardized catalog products sold via retailers in very large volumes. Industrial customers are more specialized and therefore demand more variation. In addition, each niche of industrial equipment is small in terms of the number of units sold compared to consumer products. This means that economy of scale does not drive as strongly toward standardized catalog products. The concept of one size fits all does not pay off here. The additional cost of customization is less when the volume is low. Mass customization is a growing trend in consumer products, but customization has always been a necessity in industrial equipment markets.

17.4 The Choice of Tacton Configurator

After using in-house developed configurators, FLSmidth switched to using Baans sales configurator in year 2000, for proposals as well as for order processing. That implementation has been described in Hvam et al. (2008). In 2008, the decision was made to replace that with Tacton Configurator.1 Multiple reasons contributed to that decision:

• Initially, Tacton Configurator was evaluated as a solution to generate 3D models and drawings in SolidWorks, for proposals and manufacturing, something that was not possible with the sales configurator from Baan.

• In this evaluation, FLSmidth were impressed by the ease of use and robustness of Tacton Configurator as a product configurator and sales configurator. The use of Baans sales configurator had made the organization appreciate the ease of use of constraint-based configuration, in terms of interactivity and ease of maintenance (see Section 17.5). Furthermore, Tacton Configurator was perceived as an even stronger constraint-based solution (e.g., by the ability to mix the constraint-based evaluation with sequential processing when needed, and separating the model of the user interface from how it should be rendered).

• There are obvious benefits in using the same configurator for sales, order processing, and design automation in CAD, to avoid maintaining and using multiple systems.

• Tacton had good customer references with similarly complex industrial equipment products configured as complete production systems by the configurator (e.g., TetraPak, Sidel, and Siemens Turbomachinery).

• FLSmidth liked that Tacton, as a company, was dedicated to configuration, yet big enough to handle their needs (over 50 employees at the time and now more than 100), and with a long track record of deploying and enhancing the configurator for over 10 years without impairing backward compatibility.

• When replacing the existing Baan configurator, it was also important that Tacton Configurator is XML-based and designed to be embeddable in other applications. FLSmidth were able to reuse existing integrations to legacy systems, and the user interface could be tailored to the organization’s way of working, consistently across all products.

• Tacton Configurator survived months of intensive testing to ensure that the complex requirements would be met.

17.5 Advantages and Requirements of Constraint-Based Configuration

The advantages of using a constraint-based solver engine for product configuration are well known (DeSisto, 1997; Junker, 2006).

A constraint-based interaction empowers the user to explore the vast space of configurations and find the best solution for the customers needs:

• Since many input combinations are invalid, it is important that the end-user is able to explore the possibilities by making choices in his/her preferred sequence and then view how each choice affects available alternatives for other choices.

• To find the best solution, it is sometimes necessary to make trade-offs between conflicting choices. This can be achieved by showing the user which alternatives are incompatible with previous choices and automatically inform the user how an invalid alternative can be made valid by making trade-offs with previous choices.

• Since customer specifications are typically incomplete, the constraint-solver engine should be able to validate incomplete input and find a good solution for the unspecified inputs. It should be possible to optimize the solution based on any attribute, such as cost or lead-time, or to guide the search with soft preferences.

Rules maintenance is another important challenge. We use the term rule here to denote the real-world dependency between configuration decisions, and constraint refers to the encoding of such a rule for processing by a constraint-based engine. From a rules maintenance point of view, an advantage of using a constraint-based engine is that each constraint is independent and does not assume a sequence of rules processing. This means that each configuration rule in the product can be encoded independently as a constraint without taking the other rules into account, so a rule can be added, revised, or removed without affecting the encoding of other rules. This is very important since the rules can usually not be documented from the beginning and they frequently change as the configurable product evolves over time. The difficulty of documenting all the rules before encoding them in a configurator is that it is hard for product experts to articulate all their knowledge. During testing and use of the configurator, they therefore realize that important rules have been forgotten and need to be added.

Similarly, configuration rules are often controversial and subject to change by design revisions. It is therefore essential that each rule can be encoded independently. With a sequential rules engine, such changes to the rules that are relatively small at a conceptual level can require large changes in the encoding, due to the sequential dependencies in the encoding. This can become prohibitively costly and drastically delay time-to-market.

In order to achieve these interaction requirements without additional costly and delaying rules programming, it is important that the constraint-based engine is a powerful constraint-solver, so that the interactivity is achieved automatically based on the constraints.

Beyond the constraint-solver capabilities, configuration of complex industrial equipment has the following additional requirements on the constraint-solver, and the evaluation by FLSmidth concluded that Tacton Configurator meets these requirements.

Many products are dynamic in nature. The number of component instances may vary depending on capacity requirements, and each instance may require individual configuration. In a cement plant, typical examples are products where the number of segments vary depending on length and height, such as a conveyor. This requires a constraint solver with the ability to dynamically generate new variables.

For complex products, it is not always feasible for the configurator to access all relevant data from the beginning of the configuration session, for example when the relevant component data depends on capacities and decisions that are not known from the beginning. This requires the ability to dynamically access more data on demand during the configuration session. Complex product configuration often involves sizing calculations. The constraint solver must have the ability to apply complex mathematical functions and invoke external calculations at run-time, feeding the results into further constraint processing. Configurable products may have freely customizable parameters such as dimension and positions, like the beams and support points in a conveyor. To handle this well, the configuration model must be parametric throughout the product hierarchy, and variables must be able to range over large integer or floating point domains.

The space of potential combinations to consider in a configurable product can be greater than the number of atoms in the observable universe. Although the problem of finding a solution tends to be manageable in products designed for configuration, it can for highly complex products be infeasible to solve in acceptable response time with a general purpose algorithm. It is important to also have mechanisms to guide the search heuristically in terms of the sequence of decisions without redundant encoding of constraints.

17.6 Implementing Tacton Configurator at FLSmidth

17.6.1 Configuration Modeling

Configuration modeling is the work to define the generic product structure, configurable parameters, constraints, and such in the configurator software. After an introductory three-day training session, the FLSmidth engineers were able to do all the required modeling work by themselves, using the remote product support of Tacton. The configuration modeling was initially done at the headquarters in Copenhagen. But since most of the engineering is today done at FLSmidth’s office in Chennai, India, the configuration modeling has mostly been taken over by a team of engineers there. They have very good knowledge of the products and their applications, which reduces the overhead of communication with specialists to define the rules. By using dedicated resources for configuration modeling, they can gain the experience required to model complex products.

17.6.2 Product Scope

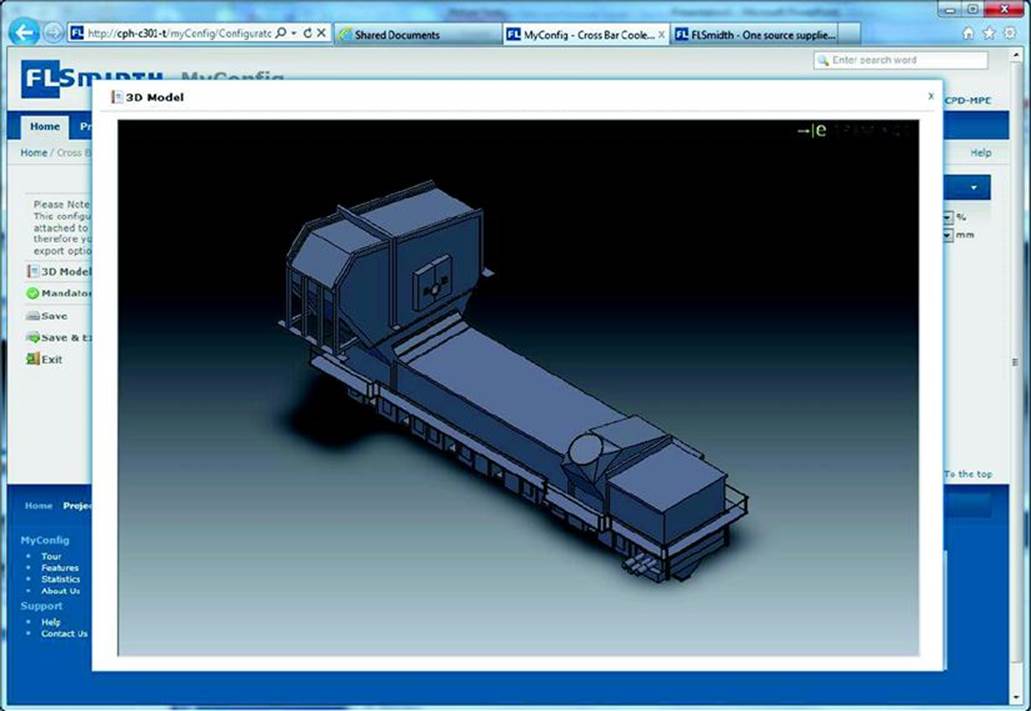

Tacton Configurator was taken into production use at FLSmidth in 2009, and is now used around the world for about 50 different products, covering the major parts of a cement plant (e.g., belt conveyors, screw conveyors, air slides, drag chains, material elevators, nuisance filters, process filters, fans, mills, kilns, and coolers).2 One example cooler product is shown in Figure 17.2.

FIGURE 17.2 A 3D model of a cross bar cooler, generated by Tacton Configurator and SolidWorks.

17.6.3 Integrated Calculations

The FLSmidth system can integrate the configurator with any external service. They currently use Mathcad for complex equipment sizing calculations like integration, differentiation, and matrix calculations. Mathcad runs invisibly on the server behind Tacton Configurator. The end user does not even realize when the program calls the external service (e.g., Mathcad) to perform a calculation.

17.6.4 Output

The following kinds of output can be generated by Tacton Configurator at FLSmidth:

• Configured product BOM structure to the legacy ERP system Atlas.

• 3D models and 2D drawings in various formats, generated by the SolidWorks integration, for proposals and manufacturing.

• Proposal documentation in PDF format.

17.6.5 Integration to SmartPlant 3D

FLSmidth are introducing a plant design software called SmartPlant 3D, from Intergraph. This tool is used to design the plant process and layout. In order to streamline the process, FLSmidth have developed an add-into SmartPlant that allows them to run Tacton Configurator within the SmartPlant user interface, to ensure that the products in the plant are correctly configured, with correct 3D models at the plant design level. The same configurations can then be accessed in the web-based configurator to generate additional documentation, mechanical CAD documents based on SolidWorks, and to process equipment orders into the ERP.

17.7 Benefits

The following are the main business benefits of the configurator perceived at FLSmidth.

17.7.1 Less Time Spent on Product Configuration

Without a configurator, it took hours to configure one product, and now it takes a few minutes. This applies to proposals as well as to order processing. A plant can contain hundreds of different configurations (many different configurable products and many different configurations of some of those products), so it adds up to a lot of time savings.

17.7.2 Shorter Lead Times

When product configuration required involvement of a few specialists, this created long lead times for proposals and order processing, beyond the effective time spent. This challenge has grown over time. FLSmidth used to have all the engineering specialists at the headquarters in Copenhagen, but has now acquired companies with different products all around the world. The product expertise is more spread out. Since FLSmidth sells complete plants with products from different places, this global distribution makes it more complicated and time consuming to generate proposals and process orders. Tacton Configurator eliminates this complication by making the expertise available anywhere. Lead times for all the product configurations in a project can be reduced from months to days.

17.7.3 More Standardized Configurations

Without the configurator, specialists tend to create special proposals that are more customized than necessary. The configurator enforces a standardization that reduces the cost of supplying the products.

17.7.4 Improved Quality of Configurations

There are an extreme number of rules to obey in configuring a cement plant. Not just product configuration, but also rules about the cement production process as well. The human element increases the risk of mistakes, and it is not feasible to involve specialists in every revision made in a project. The use of the configurator thereby reduces the risk of incorrect configurations.

17.7.5 Increased Market Share

With the drastic cuts in lead time and cost of proposals, FLSmidth can now make more proposals and gain a bigger share of the market.

17.8 Conclusion

This paper has presented FLSmidth and their experience of implementing Tacton Configurator for their cement plant products. Critical success factors are: a powerful constraint-solving engine supporting a high degree of interactivity and ease of constraint modeling, integrations to sizing calculations, integrations to related systems such as 3D CAD, plant design, and legacy ERP, as well as resources dedicated to configuration modeling who are skilled engineers knowledgeable about the products and their applications. A lot of resources are required for modeling and integration, but the benefits are very significant for the business.

References

1. DeSisto, R., 1997. Constraints Still Key for Product Configurator Deployments. Technical Report T-22-9419, Gartner, Stamford, CT.

2. Hvam L, Mortensen N, Riis H. Product Customization. Berlin, Heidelberg: Springer; 2008.

3. Junker U. Configuration. In: Rossi F, vanBeek P, Walsh T, eds. Handbook of constraint programming. Amsterdam, The Netherlands: Elsevier; 2006:837–873. Foundations of Artificial Intelligence vol. 2.

4. Tiihonen, J., Soininen, T., 1997. Product Configurators - Information System Support for Configurable Products. Technical Report TKO-B137, Helsinki University of Technology, Laboratory of Information Processing Science, also published in: Increasing Sales Productivity through the Use of Information Technology during the Sales Visit, Hewson Consulting Group.

1www.tacton.com.

2See www.flsmidth.com for additional information about these types of products.