Make: 3D Printing (2014)

Part VII. Applications

Chapter 18. Desert Manufacturer

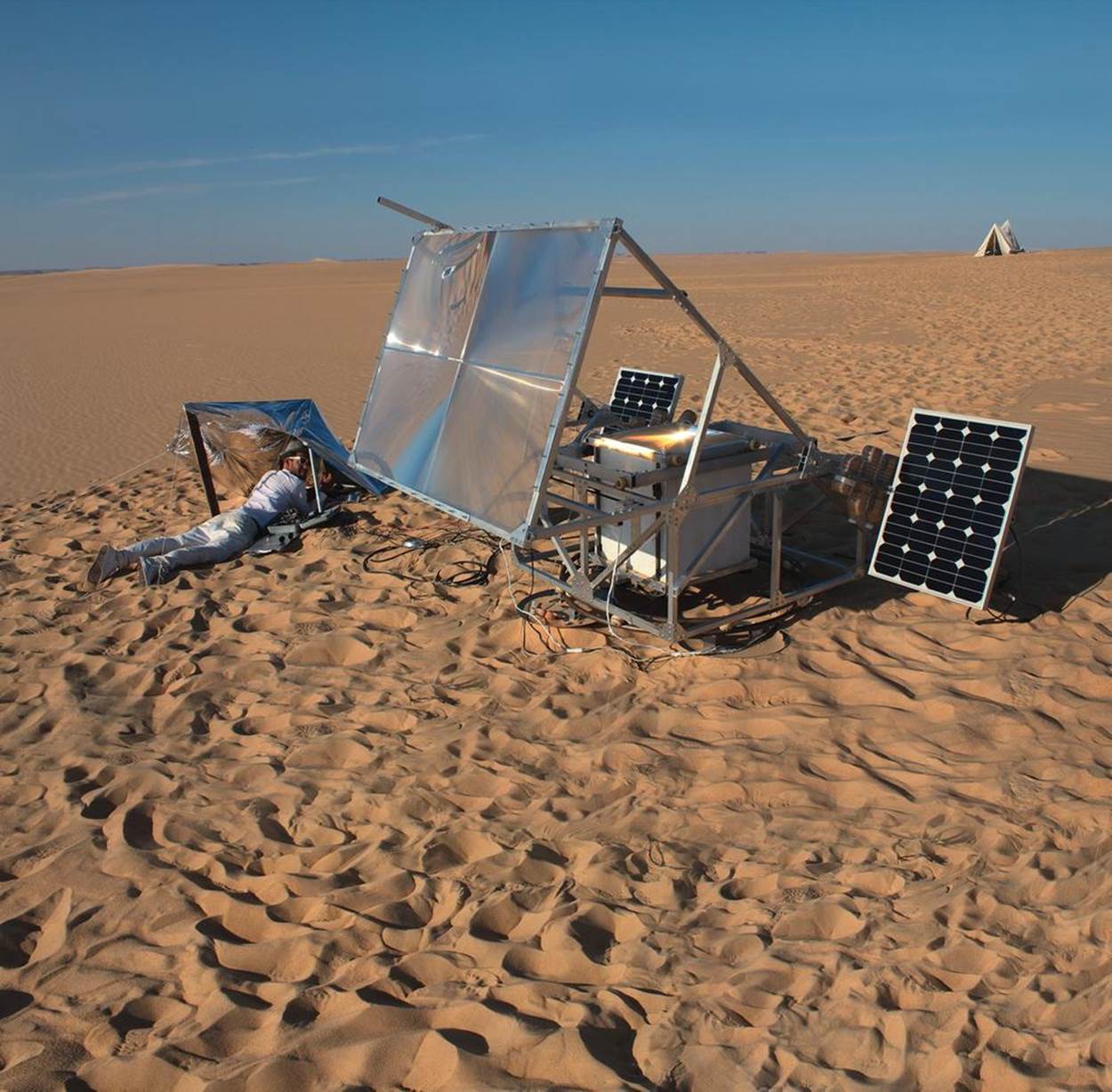

Markus Kayser’s sand and sun 3D printer.

Laura Kiniry

Think that deserts lack resources? Not to Markus Kayser. The MIT research assistant with a master’s in product design has created a 3D printer that can make glass objects using a desert’s two most abundant resources: sun and sand. “I began asking myself,” says Kayser, “what if I could build a machine which would act as a kind of translator between the two?” His Solar Sinter (Figure 18-1) is the direct result.

Figure 18-1. The Solar Sinter

Based on a type of 3D printing known as selective laser sintering (SLS), Kayser’s Solar Sinter uses the sun’s rays as a laser and sand rather than resins to create exact physical replicas of his digital designs. The printer includes a large Fresnel lens that’s always facing the sun (by way of an electronic sun-tracking device), stepper motors to move and load its sandbox, and two 60-watt photovoltaic panels that provide electricity to charge the battery that drives the motors and electronics of the machine.

His first time out with Solar Sinter, Kayser produced both a bowl and a tile, as well as a sculptural piece. “Once I input the design I’m trying to produce via an SD card,” he says, “the machine reads its code and then moves the sandbox along to the correct x and ycoordinates at 1 mm per second, while the lens focuses a light beam that produces temperatures between 1,400°C and 1,600°C, more than enough to melt the sand.” The objects (Figure 18-2) are built layer by layer over the course of several hours.

Figure 18-2. Sintered objects

“[In the future] printing directly onto the desert floor with multiple lenses melting sand into walls and eventually building architecture in desert environments could be a real prospect,” Kayser muses.

Laura Kiniry is a San Francisco-based freelance writer and regular MAKE contributor.