Mastering Autodesk Inventor 2015 and Autodesk Inventor LT 2015 (2014)

Chapter 12. Documentation

At any point in your design process, you can choose to begin documenting your design with the Autodesk® Inventor® program. Although creating drawings was traditionally something that had to wait until the design was fully complete, there are no such restrictions in Inventor. You can start to develop an annotated 2D drawing file at any point in your process. It is generally recommended, however, that you start documenting as late in the design as possible.

The ultimate goal of this chapter is to illustrate how you can use the Drawing Manager in Inventor to generate traditional 2D annotated drawings. You can then output your documentation in a variety of file formats, including DWF and PDF.

In this chapter, you'll learn to

· Create and maintain drawing templates, standards, and styles

· Generate 2D drawing views of parts, assemblies, and presentations

· Annotate drawing views of your model

Using the Drawing Manager

Once you have created your 3D design, you can choose to document it with conventional 2D orthographic drawing views and traditional drafting tools. This kind of documentation is created in the Drawing Manager environment.

These high-level Drawing Manager tasks are discussed in the following sections:

· Creating templates and styles

· Utilizing drawing resources

· Editing styles and standards

· Creating drawing views

· Annotating part drawings

· Annotating assembly drawings

· Working with sheet-metal drawings

· Working with weldment views

· Working with iParts and iAssembly drawings

· Sharing your drawings outside your workgroup

Creating Templates and Styles

Although several drawing templates are installed with Inventor, before you begin to document your own designs and models, you should create your own custom template or templates to best meet your needs. This is because most users have to adhere to a specific set of drafting standards dictated by their company, customer, or vendor specifications. These standards are typically derivatives of one of several international drafting standards such as ANSI, ISO, or DIN. Therefore, Inventor installs with a set of templates and drafting styles configured for the following international standards:

· ANSI (both Imperial and metric units)

· BSI

· DIN

· GB

· GOST

· ISO

· JIS

When creating your own custom template, it is sometimes best to start with a standard template that closely meets your requirements and modify the styles already found within it as needed. At other times it might be best to create a template from a “clean” template file that contains no styles and create them yourself.

Creating templates in the Drawing Manager is not unlike creating templates in other applications. The primary difference is that many applications use a special file format for template files, whereas Inventor uses the same file format but uses a folder location to designate all files within the template location as templates. As a result, you can use any IDW or DWG file as a drawing template; you just need to save it in the template location.

To create a drawing template from an existing, Autodesk-provided template, follow these general steps:

1. Click the New File button from the Get Started tab.

2. Choose an IDW or DWG template that is close to your needs (for instance, you might select the DIN.idw file if your company uses the DIN standard).

3. Click the Inventor button (the large I in the upper-left corner) and choose Save As![]() Save Copy As Template.

Save Copy As Template.

4. Create a new folder for your custom template location.

5. Rename your custom template to a name of your choice.

6. Make changes to the styles and standards as needed and then use the Save Copy As Template option to update the template file.

To create a drawing template from a “clean” template file that contains no styles, follow these general steps:

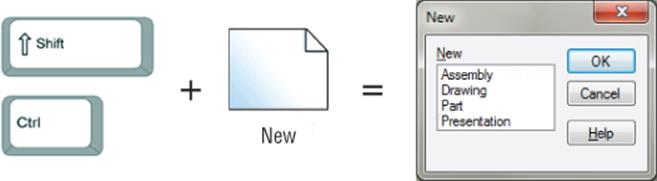

1. Hold down the Ctrl and Shift keys and click the New File button from the Get Started tab, as shown in Figure 12.1.

2. Select Drawing from the New dialog box and then click the OK button.

3. Click the Inventor button and choose Save As![]() Save Copy As Template.

Save Copy As Template.

4. Create a new folder for your custom template location.

5. Rename your custom template to a name of your choice.

6. Make changes to the styles and standards as needed and then use the Save Copy As Template option to update the template file.

Figure 12.1 Creating a new file with no styles

Understanding Template Locations

By default, Inventor templates are stored in and accessed from C:\Users\Public\Documents\Autodesk\Inventor 2015\Templates. You set the default location initially from the Tools tab by clicking the Application Options button and then selecting the File tab and entering a folder location in the Default Templates box. For stand-alone users working on a local drive, consider using the same location where you store your design projects for your template file location. If you're part of a networked design group, you should create a template folder on a shared network drive and change the default template path accordingly.

The default template location can be overridden on a per-project basis as well by setting the template location in the project file configuration. Keep in mind that if you have a template location set in Application Options and another set in the project file, the project file always takes precedence. Setting the template path in the project and having everyone use the same project file can often be the best way to ensure that all members of the design group are using the same templates.

Standard Templates

If you use the New File drop-down menus to access templates, you should know that these templates are hard-coded to use files named Standard.ipt, Standard.iam, Standard.ipn, and Standard.idw (or .dwg) located at the route of your template location. If you remove or rename the files named Standard, the drop-down menus will not work. Unfortunately, there is no way to point the drop-downs to use a template of a different name. However, if you create a copy of your template files, place them at the root of your template directory, and name them Standard, you can then access your customized templates using the standard drop-down menus.

Choosing a File Format

Prior to Inventor 2008, the IDW file format was the only native 2D file type recognized by Inventor. DWG TrueConnect, introduced with Inventor 2008, enables you to use both DWG and IDW as valid file formats in the Drawing Manager.

Using DWG as your file format enables you to open Inventor DWG files in the AutoCAD® program (or an AutoCAD vertical product such as AutoCAD® Mechanical) without going through a translation process. Although the data you create natively in Inventor cannot be manipulated directly in AutoCAD, all of the Inventor data can be viewed, measured, and printed using conventional AutoCAD commands.

By choosing DWG as your default file format, you allow downstream users of your designs to view the 2D drawing documents in AutoCAD without having to purchase or install Inventor or download the Inventor file viewer. Vendors, customers, or other internal personnel can open the native Inventor DWG file and view, measure, and print the Inventor data, or they can even add AutoCAD data to the file to create a hybrid document that can be viewed quickly and efficiently in either application. AutoCAD users with older versions of AutoCAD might need to download the Autodesk DWG TrueConnect Object Enablers to view the Inventor proxy objects. Use the search phrase TrueConnect Object Enabler to locate the downloads online.

Be Aware of File Size

Although many design departments find the convenience of having their Inventor drawings in DWG format well worth it, you should understand that Inventor DWG files will be larger than Inventor IDW files. The difference in size may vary depending on the content, but differences of up to three times as large can be common. Save a dozen typical drawing files as both Inventor DWG and IDW and compare the sizes yourself to determine which is right for you.

For Inventor users, there is essentially no difference between using DWG and using the traditional IDW file format. The native DWG file includes a Layer 0 in the layer list and an AutoCAD Blocks folder in Drawing Resources. These are the only noticeable differences between the two file formats. An IDW file can always be saved as an Inventor DWG, and vice versa, without any loss of fidelity or data. If there's a good chance of someone wanting to see a DWG version of your Inventor file, you might consider choosing DWG as your default file format. The Task Scheduler in Inventor enables you to batch-convert a set of IDW files into DWG files.

Utilizing Drawing Resources

You should customize three areas of the template to conform to your chosen drafting standards and personal preferences: Drawing Resources, Document Settings, and Styles And Standards.

Drawing resources are simply a collection of reusable sketches and formats that are stored in a drawing file. There are four types of drawing resources: sheet formats, borders, title blocks, and sketched symbols. If you've decided to use DWG as your template format, you'll notice that AutoCAD blocks are also managed as Inventor drawing resources.

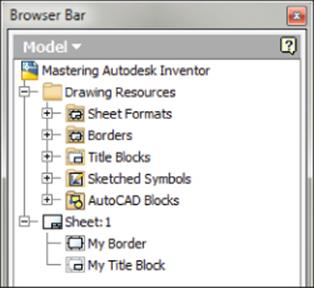

Drawing resources are accessed from your drawing browser under the Drawing Resources folder, as shown in Figure 12.2. If you expand the Drawing Resources node, you'll see a folder for each of the drawing resource types listed, and contained in each of the subfolders are drawing-resource definitions. Double-click any drawing resource to place an instance in your drawing.

Figure 12.2 The Drawing Resources node in the drawing browser

You can employ several document-management techniques with respect to templates, sheet sizes, borders, and title blocks. Although you could create and maintain separate drawing templates for each sheet size and title block you might need, it's generally recommended that a single drawing template be used to maintain each of these different configurations. In the following sections, you'll take a look at the various drawing resources.

Sheet Size

When you start a new drawing from one of the templates installed with Inventor, a border and title block are already present on the sheet, and the sheet is set to a default size. You can change the default sheet size by right-clicking the sheet in the browser and choosing Edit Sheet from the context menu. For example, if you are using the ANSI (in) template, the default sheet size is C. If you change the sheet size to D, the border on the sheet updates automatically to accommodate the change in sheet size.

To have your templates default to a different sheet size, follow these steps:

1. On the Get Started tab, click the Open button.

2. Browse to your template location and open a drawing file, such as Standard.idw (see the section “Understanding Template Locations” earlier in this chapter).

3. Right-click the sheet in the browser and choose Edit Sheet.

4. Click the arrow in the drop-down box and choose the size or sheet format from the list.

5. Click the Inventor button and choose Save (or press Ctrl+S on the keyboard).

Now when you start a new file from the template, this new sheet size will be active.

Multiple Sheets

If needed, you can add sheets to your template, which is recommended if most of your design documents require more than one sheet. To insert a new sheet into your document, follow these steps:

1. Right-click any blank area on the page and choose New Sheet (or click the New Sheet button on the Place Views tab).

2. Note that this adds the border and title block and the same size sheet as the active sheet.

3. To switch between sheets, double-click the sheet node in the browser.

Multiple Sheet Drawing Files

Use caution when creating multiple sheet sets of a sizable number because performance will likely suffer, depending on the size and complexity of the models you are detailing. Be aware too of “putting all of your eggs in one basket” should a file become corrupted or lost. It is generally considered best practice to create a single drawing for each part number in an assembly, rather than attempting to manage an entire drawing set for an assembly in a single drawing file. However, certain industries approach this aspect of drawing sets differently

Creating a Border

The default border used on the Inventor templates may not meet your needs. To create a new border, you'll first follow these steps to remove the instance of the old border:

1. Expand the sheet node in the browser.

2. Right-click the border instance, and choose Delete.

Doing so removes the instance of the border from the sheet. The border definition is still stored in the Borders folder of the Drawing Resources node. To create a new, custom border in your template, follow these steps:

1. In your template file, expand the Drawing Resources node in the browser.

2. Right-click the Borders folder and choose Define New Border. You might have the option to choose Define New Zone Border, but you'll use a simple border here to explore the steps required. Here is a brief description of both border types:

Define New Zone Border Brings up an input dialog box where you can specify the number of horizontal and vertical zones, alpha or numeric zone labels, font and font size, and margin spacing. A sketch is created from your input automatically.

Define New Border Creates a sketch with the four corners of the sheet projected in. You can sketch a rectangle to create a simple custom border and use dimensions to specify the margins from the sheet corners. Dimensioning to the sheet corners allows your border to automatically resize to any sheet size, holding the specified margins. Borders can be as simple or complex as required, but the sketch should always be fully constrained.

3. On the Sketch tab, select the Two Point Rectangle tool.

4. Sketch a small rectangle on the screen; ensure that you do not sketch it on the sheet corners because this will constrain the rectangle to the corners.

5. On the Sketch tab, select the Dimension tool.

6. Place dimensions from the corners of your rectangle to the projected corner points of the sheet so that the edges of the rectangle will be 10 mm from the edge of the sheet.

Formatting Color and Line Weight in a Border Sketch

By default, all geometry created in a border is set on a layer named Border. You can change the color and line weight of that layer to modify all the entities of your border, or you can override the properties of individual entities as required. To do the latter, right-click the object you want to modify and select Properties.

7. When your border sketch is complete, right-click and choose Save Border (or click the Finish Sketch button on the Sketch tab).

8. Enter the name of your border definition.

9. Click Save.

10.Look in the Borders folder of the Drawing Resources node in the browser for your new border definition.

11.Right-click your border and choose Insert to place an instance of it on the current sheet.

12.If you need to modify the border definition, right-click your border instance or the definition in Drawing Resources and choose Edit Definition or Edit.

Because the border is dimensioned to the edge/corners of the sheet, if you edit the sheet size, the border will automatically resize as needed, holding the margin distance, 10 mm in this example.

Creating a Title Block

Title blocks are customized in much the same way borders are customized. Title blocks typically contain more text-based information than borders, so the focus will be on creating sketch text in this section. There are three common ways of creating a custom title block:

· You can use an existing title block originally drawn in AutoCAD.

· You can modify a default Inventor title block.

· You can create one completely from scratch in Inventor, drawing the line work and inserting the text fields.

In this section, you will bring in an existing AutoCAD title block and make it intelligent to Inventor. In doing so, you will explore the tools used to create a title block employed in the other tile block creation methods mentioned. You should probably first delete the default title block from your current sheet before creating a new title block, just to reduce confusion.

If you have not already downloaded the Chapter 12 files from www.sybex.com/go/masteringinventor2015, please refer to the “What You Will Need” section of the introduction for the download and setup instructions.

Once you're sure you have the Chapter 12 files in place, follow these steps to explore the creation of a title block:

1. From your template file (or any standard Inventor drawing file), expand the sheet node in the browser.

2. Right-click the title block instance and choose Delete.

3. On the Get Started tab, click the Open button.

4. Browse for mi_12a_033.dwg in the Chapter 12 directory of your Mastering Inventor 2015 folder. You may need to change the Files Of Type drop-down to All Files or AutoCAD Drawings (*.dwg) to locate the file.

5. Click the Options button in the Open dialog box.

6. Ensure that Open is selected; otherwise, Inventor will take you to the DWG/DXF File Wizard.

7. Click the OK button.

8. Click the Open button.

Notice that when you open an AutoCAD drawing in Inventor, you can view and measure the file. You should see a black background, and if you check the browser, you will see that you are viewing the model space environment of the file.

9. Right-click the title block and choose Copy.

10.Use the Open Documents tabs at the bottom of the screen to switch back to your template file (or press Ctrl+Tab on the keyboard).

11.In the Drawing Resources folder in the browser, right-click the Title Blocks folder and choose Define New Title Block. This will place you in the Sketch environment.

12.Right-click in the graphics area and choose Paste.

13.Click in the middle of the sheet to place the title block.

You'll notice that the line work is underconstrained and not dimensioned at all. You can take the time to dimension it if you'd like, but because this will become a block and therefore a static entity, you most likely will not need to do so.

Continue adding intelligence to the text now.

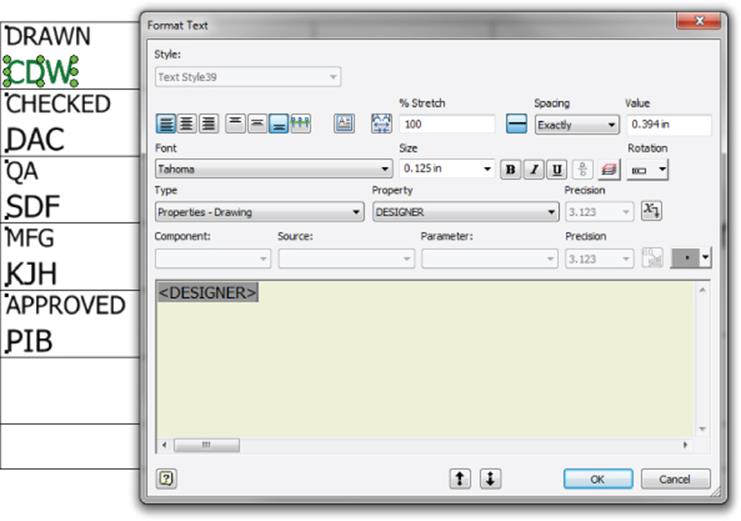

14.Right-click the text field containing CDW and choose Edit Text.

15.In the Format Text dialog box, select the text and press Delete on the keyboard.

16.Locate the Type drop-down and set it to Properties–Drawing, as shown in Figure 12.3.

17.Set the Property drop-down to Designer.

18.

Click the Add Text Parameter button to set the Designer property to the text field.

19.Click the OK button.

20.Repeat steps 14 through 19 for the date field directly to the right of the field you just edited. Use the Creation Date property instead of Designer.

21.Right-click and choose Save Title Block (or click the Finish Sketch button on the Sketch tab).

22.Enter a name for the new title block definition, such as My Title Block.

23.Look in the Title Block folder of the Drawing Resources node in the browser for your new title-block definition.

24.Right-click your title block and choose Insert to place an instance of it on the current sheet.

25.If you need to modify the title block definition, right-click your title block instance or the definition in Drawing Resources and choose Edit Definition or Edit.

Figure 12.3 Customizing the title block

Obviously, you have not configured the entire title block at this point, but before going any further, it is important to understand where the properties you linked to the title block text fields are coming from. You can find these properties in the file iProperties. Follow these steps to change an iProperty in the drawing file and see that change show up in the title block:

1. Click the Inventor button and choose iProperties.

2. On the iProperties Project tab, change the Designer input to Test Designer.

3. Change the Creation Date input field to 1/1/2015.

4. Click the OK button to apply the changes and close the iProperties dialog box.

Your title block will have updated the two fields automatically based on the iProperty changes you made, demonstrating that you have linked those fields to the iProperties of this particular drawing file. If you intend to use this title block for your drawing template, you should continue to configure your title block to retrieve the iProperties needed, until all of the fields are automatically filled out by updating the iProperties. For now, you can close the file you have open without saving changes and continue to the next section to learn more about iProperties.

iProperties and Title Blocks

Each Inventor file has its own set of iProperties, allowing you to pull information from that file into your title block. There are two distinct methods you can use to retrieve iProperties into your title block:

· You can retrieve iProperties from the drawing file.

· You can retrieve iProperties from the model file that is referenced in the drawing file.

The following is a list of the standard iProperties available. Each of these can be accessed from the Type drop-down in the Text Format dialog box as described in the previous steps. You'll learn more about iProperties in Chapter 13, “Tools Overview.”

|

Author |

Designer |

Mfg Approved Date |

|

Authority |

Eng Approval Date |

Part Number |

|

Category |

Eng Approved By |

Project |

|

Checked By |

Engineer |

Revision Number |

|

Checked Date |

Estimated Cost |

Status |

|

Comments |

Filename |

Stock Number |

|

Company |

Filename And Path |

Subject |

|

Cost Center |

Keywords |

Title |

|

Creation Date |

Manager |

Vendor |

|

Description |

Mfg Approved By |

Weblink |

|

Design Date |

Linking Your Model and Drawing iProperties

Often, you will want the iProperties for the model file and drawing file to match. You can use the Copy Model iProperty Settings option to have this happen automatically.

To do so, open your drawing template, select the Tools tab, click Document Settings, select the Drawing tab in the dialog box that opens, and click the Copy Model iProperty Settings button at the bottom. You can have some or all of the model properties copied to the drawing.

Note that once copied, the properties do not update automatically when they are changed in the model. To update them, select the Manage tab and click Update Copied Model iProperties.

Follow these steps to modify a title block so it is pulling information from the model iProperties. You'll note that this title block is calling the model filename iProperty for the drawing title. Most of the other fields are being pulled from the drawing file's iProperties. The field you will be modifying is static and needs to be set to pull from the model file's iProperties. Here are the steps:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_024.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder.

3. Expand the sheet node in the browser (if it is not already expanded).

4. Right-click the title block instance (named MI_TB_04) in the browser and choose Edit Definition.

5. Zoom up on the title block and locate the Part Number area toward the bottom.

6. Right-click the text field showing ### and choose Edit Text.

7. In the Format Text dialog box, select the text (###) and press Delete on the keyboard.

8. Locate the Type drop-down and choose Properties–Model.

9. Set the Property drop-down to Part Number.

10.Click the Add Text Parameter button to set the property to the text field.

11.Click the OK button.

12.Right-click and choose Save Title Block (or click the Finish Sketch button on the Sketch tab).

13.Click Yes at the Save Edits prompt.

To ensure that the part number in the title block is coming from the part model and not the drawing file, you will open the model file and change its iProperties.

14.Locate the View2:Arbor_Frame.ipt node in the browser and then right-click it and choose Open.

15.Once the part model is open, right-click the top-level node (Arbor_Frame.ipt) in the browser and choose iProperties.

16.Select the Project tab and then edit the Part Number field to read 98765.

17.Click the Apply button and then the Close button.

18.Use the Open Documents tabs at the bottom of the screen to switch back to the drawing file (or use Ctrl+Tab to switch between all open documents).

You will see that the title block has read the model part number and displays the change in the Part Number field.

Experiment with the title block to understand the way it works with iProperties from the model, and then you can close the file without saving changes. You might notice that this title block does not contain dimensions. Instead, the objects within it were anchored in place using sketch constraints.

The i CHECK IT Add-in for Inventor

There are several add-ins available that check to ensure that users have not forgotten to fill out required iProperties. One such add-in is i CHECK IT from Tata Technologies. i CHECK IT goes far beyond just checking iProperties, however; it will also check to ensure that the filenaming convention has been followed, that the first sketch of a model is constrained to the origin, that all sketches are fully constrained, that only approved dimension styles are used, and much more. There are more than 100 checks that can be defined. Visit the following page to download a 30-day free trial version:

http://apps.exchange.autodesk.com/INVNTOR/Home/Index

General File Properties and Title Blocks

In addition to iProperties, you can use some other standard file properties to fill out your title block automatically. You can access them from the Type drop-down in the Text Format dialog box just as you did the iProperties. Table 12.1 lists several general properties that can be called into a text field.

Table 12.1 Available properties

|

Physical properties of the model |

General drawing properties |

Drawing sheet properties |

Sheet-metal flat pattern properties |

|

Area |

Number Of Sheets |

Sheet Number |

Flat Area |

|

Density |

Sheet Revision |

Flat Length |

|

|

Mass |

Sheet Size |

Flat Width |

|

|

Volume |

Follow these steps to set up the sheet number area of the title block to call on general file properties of the drawing file to automatically fill out the title block:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_025.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder.

3. Expand the sheet node in the browser.

4. Right-click the title block instance (named MI_TB_05) and choose Edit Definition.

5. Zoom up on the title block and locate the SHEET ?? OF ??? area at the bottom right.

6. Right-click the text field showing SHEET ?? OF ??? and choose Edit Text.

7. In the Format Text dialog box, select the two question marks between the word SHEET and the word OF and press Delete on the keyboard.

8. Locate the Type drop-down and choose Sheet Properties.

9. Set the Property drop-down to Sheet Number.

10.Click the Add Text Parameter button to set the Number Of Sheets property to the text field.

11.Still in the Format Text dialog box, select the three question marks after the word OF and press Delete on the keyboard.

12.Locate the Type drop-down and choose Drawing Properties. (Note that there is one called Properties–Drawing also, so ensure that you have the correct one.)

13.Set the Property drop-down to Number Of Sheets.

14.Click the Add Text Parameter button to set the Sheet Number property to the text field.

15.Ensure that the text in the text displays as SHEET <Sheet Number> OF <Number of sheets>. Then click the OK button.

16.Right-click and choose Save Title Block (or click the Finish Sketch button on the Sketch tab).

17.Click Yes at the Save Edits prompt.

Experiment with adding new sheets and reordering the sheets (just drag and drop the sheets in the browser) to see how the title block updates, and then you can close the file without saving changes.

Prompted Entry

You can also create fields in your title block to enter information manually using what is known as a prompted entry. Prompted entry text is keyed in by the user and not retrieved from the file properties in the way that iProperties are. Because of this, experienced Inventor users will tell you that iProperties are favored over prompted entries for two reasons.

First, information entered into a prompted entry field is stored in that one title-block instance and nowhere else. If you need to update the title block for your entire drawing library at some point in the future, you can do so easily with the Drawing Resource Transfer Wizard, which can swap out old title-block definitions with a new one, en masse. (See Chapter 13 for more on this Inventor tool.) This works well when title blocks have been populated with iProperties because the information resides in the file, not the title block. However, if a prompted entry was used, that information will not be carried over because it exists only in the old title-block instance.

Second, since iProperties are stored in the file, there are a couple of important tasks that can be performed on them:

· iProperties can be viewed, searched, and copied easily using a number of tools such as Find, Design Assistant, and Vault.

· Non-Inventor users can use iProperties to sign off on drawings without opening the file in Inventor.

Getting in the habit of using iProperties will pay large dividends in the future, once you have created many Inventor files. With these things in mind, you should use prompted entries in title blocks rarely. Here are the steps for creating a prompted entry in a title block if you determine that it is required:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_026.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder.

3. Expand the sheet node in the browser.

4. Right-click the title block instance (named MI_TB_06) and choose Edit Definition.

5. Zoom up on the title block and locate the Tracking Code area at the bottom left.

6. Right-click the text field showing ##### and choose Edit Text.

7. Locate the Type drop-down and choose Prompted Entry.

8. Replace ##### with Enter Tracking Code.

9. Click the OK button.

10.Right-click any empty space in the graphics area and choose Save Title Block.

11.Click Yes at the Save Edits prompt.

12.Enter 12345 for the tracking code, when prompted.

13.Click the OK button.

You can edit a prompted entry in a title block by expanding the block instance in the browser and double-clicking the Field Text node. If no prompted entry is established, you will only be able to view the fields. If you edit Sheet 2 and add the MI_TB_06 title block to it, you will immediately be prompted for the tracking-code entry. When you've finished exploring prompted entries, you can close the file without saving changes.

Sketched Symbols

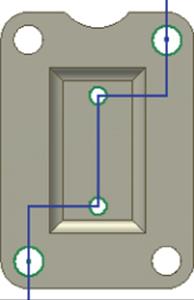

Sketched symbols are created, edited, placed, and managed much like other drawing resources, but there is no limit to the number of sketch symbol instances you can place on a sheet. Like other drawing resource definitions, sketched symbols are placed by double-clicking the definition node in the browser or using the User Symbols button on the Symbols panel of the Annotate tab.

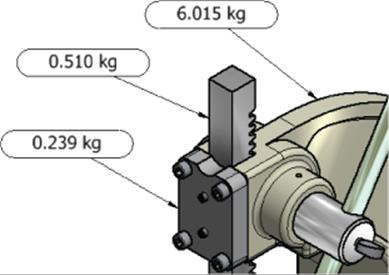

Sketched symbols can optionally include a leader. Using a leader, you can associate a sketch symbol with a model so that model-specific properties can be displayed in the symbol. For example, you could create a sketch symbol that calls out a component's mass:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_030.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder.

3. Expand the Drawing Resources browser folder.

4. Right-click the Sketch Symbol folder and select Define New Symbol.

5. In the Draw panel of the Sketch tab, click the Text button (or press T on the keyboard).

6. Click anywhere on the page to set the text location.

7. In the Format Text dialog box, type in a static text string that reads Mass: (be sure to include a space after the colon).

8. Locate the Type drop-down and choose Physical Properties–Model.

9. Set the Property drop-down to MASS.

10.Click the Add Text Parameter button to set the MASS property to the text field.

11.Click the OK button.

12.Right-click anywhere in the graphics area and choose the OK button.

13.Choose Save Sketched Symbol from the context menu.

14.Enter Mass for the name and click Save.

15.To insert the symbol into the drawing, right-click the Mass sketch symbol definition in the drawing browser and select Symbols.

16.Ensure that the Mass symbol is chosen from the list on the left side of the Symbols dialog box and select the Leader option.

17.Click the OK button.

18.Click any model edge in the drawing view.

19.Click again for each leader vertex you'd like and then choose Continue from the context menu.

20.Continue to place additional symbol instances, but be sure to point to a different Arbor Press component each time.

You'll notice that the symbol in Figure 12.4 has a bit more geometry than the simple symbol you just created. You can make a sketch symbol as elaborate as you like, but for the purposes of this exercise, the Mass property reference is all that is required. A finished symbol named Mass_2 has been created for you in this drawing file. If the mass shows up as N/A, it indicates that the model needs to be updated. You can open the assembly model, select the Manage tab, and click the Update Mass button to do this. Then return to the drawing to see the update.

Figure 12.4 Applying sketched symbols to a drawing view

Formatting Your Text to Center Your Symbols

Generally, text objects are created with a justification setting other than middle center. However, a middle-center justification will allow you to center your text in the symbol geometry by using sketch constraints.

Here are some more sketch symbol points to remember:

· Sketched symbols are often used to create standard blocks of text notes.

· Sketched symbols can be placed as needed on new documents or placed on the template itself, which can be useful for standard drawing notes that will be placed in every drawing.

· If there is field text in the sketch symbol, it becomes populated just like title block field text when you create a new drawing.

· If you need to establish a symbol reference to a model but do not want to see the leader, you can edit the symbol and then double-click or select Edit Symbol from the symbol's context menu and uncheck the leader Visibility option.

· You cannot graphically rotate or scale static sketched symbols as you can symbols that are not static.

· Sketched symbols placed by double-clicking the definition are set to Static by default; you can set this option prior to placement if you click the User button on the Symbols panel of the Annotate tab.

· Sketched symbols placed by right-clicking the definition and choosing Symbols or by clicking the User button on the Symbols panel of the Annotate tab are set to have more controls than static symbols initially.

· You can switch a static symbol to be not static by right-clicking it and choosing Edit Symbol.

· When you mouse over a sketch symbol that is not static, a single blue hot point is shown on the center top of the symbol and four yellow hot points are displayed at the four corners of the symbol.

· Clicking and dragging the blue hot point causes the symbol to rotate, whereas clicking and dragging any of the yellow hot points enables dynamic scaling.

· You can change the insert point of a sketched symbol by adding a point to the sketch and then using the Set Insertion Point Grip button to mark it as the insertion point. This button can be found next to the Driven Dimension button on the Format panel of the Sketch tab.

· Sketched symbols can be patterned by right-clicking an instance of a symbol and choosing Pattern Symbol.

· Sketched symbols are a good place to use prompted entry text.

AutoCAD Blocks

Blocks created in AutoCAD can be used in Inventor in the same way sketched symbols are used. However, differences exist between the way they are created and used. AutoCAD blocks are available for use only when you are using an Inventor DWG file and cannot be used in an Inventor IDW file. Also, you cannot create or edit AutoCAD blocks in Inventor. There are two ways to bring blocks into an Inventor DWG file:

· Copy and paste from AutoCAD.

· Right-click the AutoCAD Blocks folder found in the Drawing Resources folder and choose Import AutoCAD.

Here are some other points to remember about blocks:

· Once blocks are imported, you can scale, rotate, and pattern them by right-clicking the block instance.

· Blocks containing attributes can be modified by right-clicking the block instance and choosing Edit Attributes.

· Color and layer properties can be modified by right-clicking the block instance and choosing Properties.

· You can create a block from your drawing views by right-clicking the browser node for the view and selecting Insert In Model Space from the context menu.

Sheet Formats

Sheet formats are preset collections of drawing sheets, borders, title blocks, sketched symbols, and/or base and projected views. They essentially give you the ability to quickly generate multiview drawings just by referencing a single model file. To create a multiview drawing, follow these steps:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_037.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder.

3. Expand the Drawing Resources browser folder.

4. Expand the Sheet Formats folder.

5. Right-click the A Size, 4 Views, 1/2 Scale format, and choose New Sheet.

6. Browse for mi_12a_038.ipt in the Chapter 12 directory of your Mastering Inventor 2015 folder and click the Open button.

7. Click the OK button in the Select Component dialog box.

You will note that a new sheet has been created to the specifications of the sheet format and set active. This technique is ideal if you find yourself detailing similar designs of common size and complexity. You can close the file without saving changes.

To save your own sheet format, set up your sheet the way you like it, right-click the active sheet node in the browser, select Create Sheet Format, and then name the sheet format as you'd like.

Here are some more sheet format points to remember:

· Only base and projected views are saved in a sheet format. Section, detail, and other such views will not be included.

· Placed drawing resources such as standard notes (in the form of sketched symbols) can be included in a sheet format.

· You can preload your drawing template as a sheet format as well. Simply open a template, create base and projected views of any model, and then save and close them. When you next use your template for a new drawing, you'll be immediately prompted to reference a model file, and the drawing views will be automatically created.

Transfer Drawing Resources

You can copy drawing resource definitions from drawing to drawing by following these steps:

1. Right-click the definition of the title block, sketched symbol, or other drawing resource you want to copy and select Copy from the context menu.

2. Right-click the appropriate drawing resource node (or the Drawing Resources folder itself in the target document).

3. Select Paste.

You can use this technique to add new drawing resources and update existing resources. You can also select the entire Drawing Resources folder in one drawing and paste it into the Drawing Resources folder of another drawing. You will be prompted to replace or make a new instance of any duplicate resources.

The copy-and-paste technique is efficient for single changes or transfers between two drawings, but to push one or more new or updated design resource definitions to multiple drawings, use the Drawing Resource Transfer Wizard discussed in Chapter 13.

Area Code Changes

In 2002, the phone number area code for Rochester, New York, and the surrounding areas changed from 716 to 585. This meant that every manufacturing, engineering, and architectural group in the area suddenly had hundreds and thousands of working drawings with the wrong phone number in the title block. Many companies that wanted or needed to update their title blocks had to manually copy and paste title blocks on each drawing in their archives (the savvier groups wrote custom application scripts to perform this task). Unfortunately, the Drawing Resource Transfer Wizard was not released until some years later. It would have likely saved thousands of hours of work.

Editing Styles and Standards

As it does with color, material, lighting, and sheet-metal styles in the modeling environment, the Drawing Manager makes heavy use of XML-based styles. The basic framework of drawing styles is no different from those in the modeling environment. Drawing style settings are viewed and edited using the Style And Standard Editor dialog box. They can be shared among a workgroup via the library that contains the modeling styles, and they can be imported and exported as stand-alone XML files.

Drawing styles differ from modeling styles more in concept than in practice, however, and the drawing styles themselves are a collection of drafting rules that include the following and many more:

· Dimension styles

· Text styles

· Balloon styles

Styles in Use, a Case Study

A standard is a collection of styles. A company called Mastering Inventor, Inc., has created a basic company standard using dimension styles, text styles, and balloon styles. The various styles' names are listed here, followed by the style category:

1. Dim_Shop: Dimension style

2. Dim_Client: Dimension style

3. Dim_Marketing: Dimension style

4. Text_125: Text style

5. Text_250: Text style

6. Text_Script: Text style

7. Text_Partslist: Text style

8. Balloon_Item_Count: Balloon style

9. Balloon_Partnumber: Balloon style

10.Balloon_Partname: Balloon style

Having these styles set up allows Mastering Inventor, Inc., to create three types of standard drawings:

· The majority of the drawings are created for use by the shop floor to make parts. These drawings are required to be clear, concise, and detailed with tolerances.

· Also required are client approval drawings, showing some design specifics but also purposely limited in detail so that a competitor cannot manufacture from them.

· Occasionally, stylized drawings for use on the company web page or at trade shows are created.

To facilitate this, Mastering Inventor, Inc., has created a separate dimension style for each of these three drawing types. The company has also created several different text styles, which are called into the dimension styles and used independently as notes, and so on. Also created were balloon styles, each set up to call different iProperties from the models. This works well because Inventor users can quickly switch to the style needed without having to stop and define a style, override another style, or worry about not maintaining consistency and/or corrupting the company standard.

The question then becomes this: If this company has three sets of styles in the company standard, how does Inventor know which one to use by default? The answer is object defaults.

To explore the use of styles, study the scenario described in the Real World Scenario entitled “Styles in Use, a Case Study,” and refer to it in the example to come.

Object Defaults

The true key to understanding how styles are used to determine the formatting of everything you can create on a drawing sheet is the notion of object defaults.

In the case-study example, it is clear that the majority of a designer's day-to-day drawing work is focused on creating prints for manufacturing. Therefore, the styles used for that type of drawing would be the styles set up as the object defaults. Object defaults are automatically set as the current styles in the template drawings. For this scenario, the object defaults would likely be configured as shown in Table 12.2.

Table 12.2 Object-default styles

|

Style type |

Object default |

|

Dimension style |

Dim_Shop |

|

Text style |

Text_125 |

|

Balloon style |

Balloon_Item_Count |

Now that you understand the overall concept of object defaults, follow these steps to see how they are managed:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_041.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder.

3. Zoom to the top of the drawing, and note the three balloons.

Each balloon on the sheet is using a different balloon style. Each balloon style is calling a different set of iProperties, as you will see by comparing the balloons to the parts list. To see how object defaults work, you'll now create more balloons on the ram part, which is the square-shaped bar with teeth cut into it.

4. Select the Annotate tab and then click the Balloon button (on the right side).

5. Note the two style drop-downs all the way to the right of the Annotate tab. The top one controls layers, and the second controls styles.

6. Click the Style drop-down to show the available balloon styles. You should see one style denoted as By Standard and three listed below that, one of which is the one called out in the By Standard line.

7. Select the Balloon_Partname style from the list and then select any edge of the ram.

8. Drag out and place the balloon on the page by clicking.

9. Right-click and choose Continue (or press Enter on the keyboard).

10.Repeat steps 6 through 9 for the other two balloon styles, until you have three balloons on the ram part, each using a different balloon style.

11.Right-click and choose Cancel when complete.

This demonstrates the use of different styles and shows that one of these styles is set as the company standard default style. You'll now go into the Style And Standard Editor and change the object default for the balloon style.

12.Select the Manage tab and then click the Styles Editor button. You will be presented with the Style And Standard Editor. (It may take a few seconds to index the styles initially.)

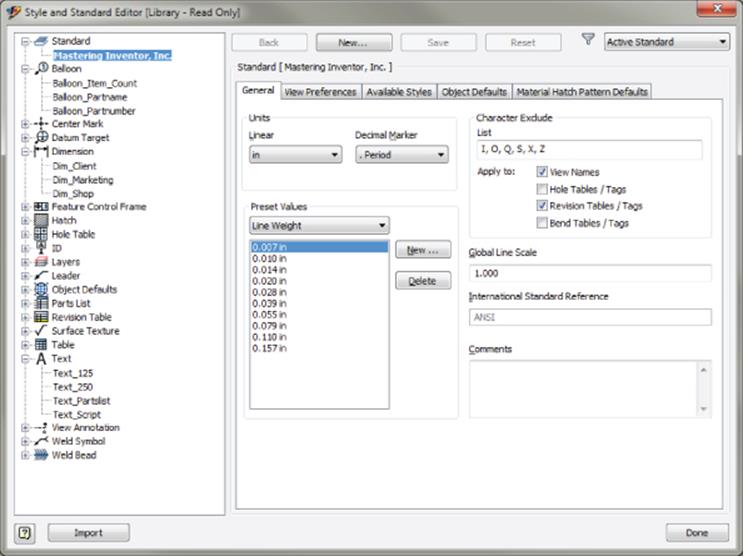

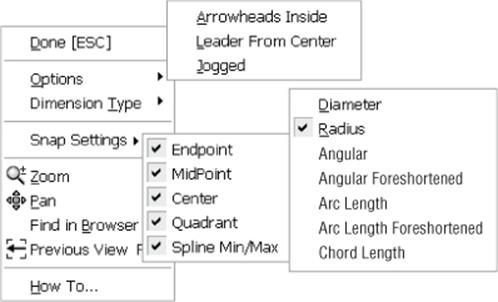

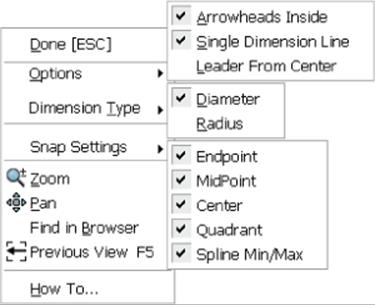

13.Ensure that the filter at the top right is set to Active Standard and then use the plus sign to expand the Balloon, Dimension, Object Defaults, and Text style categories, as shown in Figure 12.5. Note the style names listed under each style category.

Look at the following items:

· Company Standard (Mastering Inventor, Inc.)

· Balloon styles

· Dimension styles

· Object Defaults (Mastering Inventor, Inc.)

· Text styles

14.Click Object Defaults (MI, Inc.).

15.Locate the Balloon row in the Object Type column.

16.Click the Object Style cell for the Balloon row and set the drop-down to Balloon_Item_Count.

17.Click the Layer cell for the Balloon row and set the drop-down to Balloons.

18.Click the Save button at the top of the editor.

19.Click Done to exit the editor.

20.Select the Balloon button from the right of the Annotate tab.

21.Select any edge of the ram and place another balloon just as you did before.

22.Note that the Balloon tool now defaults to the Balloon_Item_Count style and is placed on the Balloon layer.

Figure 12.5 Standards, styles, and object defaults

When setting object defaults, you typically want to use the most common style. Of course, you can always use another style by manually selecting the style from the Style drop-down as you place the object. You can also select an existing object, and the Style and Layer drop-downs will display that object's style and layer, allowing you to change layer and style assignment as needed.

Objects that have been set to a specific style, rather than following the By Standard option, will not update if you make any modifications to the object defaults. However, the objects will update if the specific style is updated. A quick way to get a set of objects (like your balloons, for example) to return to their object default is to window-select or Ctrl+click the objects on the screen and then select By Standard from the style drop-down. All the objects will update to use the newly selected standard.

Set the Style Drop-Down to Last Used

You can set the Style drop-down to remember the last-used object style by selecting the Tools tab, clicking the Application Options tab, and then selecting the Drawing tab. On the right side of the Drawing tab, you will find a Default Object Style setting. If you set the drop-down to Last Used, the last-used object and dimension style is the default. For example, if you are placing dimensions on a drawing using a fractional style but the decimal style is the default, you can set the application option to Last Used so you do not need to keep changing the style back to fractional every time you access the dimension style. The Last Used setting is for the current editing session for the drawing, so if you close the file and reopen it, the Object Default will list again, until it's changed.

Creating Styles

As evident in the balloon example, you can have multiple styles for the same object type. Or you can have a single style that you always use. It's up to you to choose how many styles you have for each type, and this will be dictated largely by need. Although this section will not go through all the settings for all the styles, you will explore how to create and configure a new style as a foundation to creating all style types. Here are the steps:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_046.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder.

3. Select the Manage tab and click the Styles Editor button.

4. Ensure that the filter drop-down at the top right is set to Active Standard and then in the left pane expand the Text node to see the list of text styles.

5. Expand the Balloon node to see the list of balloon styles.

6. Click the balloon style named Balloon_Partnumber to display the style settings in the right pane.

7. Click the New button at the top of the editor dialog box and enter Balloon_Item_Qty for the style name.

8. Ensure that the Add To Standard check box is selected and click the OK button.

9. In the Balloon Style settings, under the Sub-Styles section, use the drop-down to set the text style to use the style called Text_Script.

10.Click the Shape button and select the second shape (Circular–2 Entries) from the list.

11.Below that, in the Property Display area, click the Property Chooser button.

12.Click the Part Number property in the right pane and click the Remove button to take it out of the property list for this balloon style.

13.In the Left pane, locate the ITEM and ITEM QTY properties and use the Add button to pull them into the right pane. Do this one at a time.

14.Use the Move Down and Move Up buttons to set ITEM as the top property.

15.Click the OK button.

16.Click the Save button.

17.Click the Help button in the lower-left corner of the Style And Standard Editor, and notice that this takes you to a listing and description of each setting in the balloon style. This is true of all of the style types.

18.Close the Help dialog box and click Done in the Style Editor.

19.Select the Annotate tab and click the Balloon button.

20.From the Styles drop-down on the far right of the Annotate tab, choose your new Balloon style, Balloon_Item_Qty, from the list.

21.Click the edges of parts to place on the drawing balloons that will list the item number and quantity using a script font for the text.

Although the settings for each style type vary, the steps for creating them remain consistent throughout all styles. The steps are as follows:

1. Create a new style based on an existing style.

2. Specify substyles (if applicable).

3. Configure the style settings as desired.

4. Save the new style.

Working with Substyles

A basic example of a substyle in the modeling environment is the color style, which is a substyle of the material style. Once you apply a new material to a part, not only are you changing its physical parameters, but you're also potentially changing its color so that it shows the material's color substyle. In the previous balloon style exercise, you used a text substyle called Text_Script when creating the balloon style.

The use of substyles in the Drawing Manager is extensive. Almost every kind of annotation you create in a drawing contains some kind of text (dimensions, weld symbols, and parts lists), and many make use of leaders. The text style and leader style, therefore, are frequently used as substyles of other styles. This basically provides one-stop shopping if you want to quickly change all the text on your document. If you wanted to change the font for all text, for example, you wouldn't have to go to the parts-list style and change the font, then to the dimension style and change the font, and so on; instead, you would simply change just one or two text styles that are being called into those other styles.

Substyles are coupled with their parent styles, which means a substyle cannot be purged if it's in use by another style. If you cache a high-level style into your document from the library or if you save a high-level style into the library from your file, all substyles participate in those operations.

Styles are extremely powerful formatting tools that enable you to quickly change the entire face of a document. This also serves as a warning that modifying styles without understanding how they work can quickly generate unexpected results.

Take the Time to Understand Styles

Although there's probably never been a single person who decided to use Inventor just for the “exciting” styles and standards tools, these tools are extremely powerful, and you'll be doing yourself a disservice if you don't spend some time getting to know them. They may seem complex at first, but once you understand them, they will become powerful tools. Play around with changing styles in a scratch drawing and see how the annotations change.

Another good resource for learning more about styles can be found by inserting the installation disc and clicking the Read The Documentation link on the first screen of the setup program; then click Fundamentals For The Autodesk Inventor CAD Manager under the Installation Guides category. This will open the CAD Manager Fundamentals PDF file. If you do not have the installation discs, you can find an older copy of this document included with the tutorial files in the Chapter 12 directory of the Mastering Inventor 2015 folder.

Once you have a good understanding of styles, sit down with your design group and come up with a set of standards with which everyone is happy. Apply these styles to your documents and use them for a while. One of the great aspects of the style library is that if you want to make a change, you can make it to the library, and everyone will have access to this new/changed style each time they open a file.

Drawing Style Administration

Each drawing template that comes with Inventor has a full set of styles saved (cached) in the drawing document. Although you can use the style library as a sharing and update tool, there is no direct link between objects on your sheet and styles in your library. Any in-use style is loaded into your document either automatically or manually.

If your project is set to use the style library (the Use Style Library setting is Yes or Read Only), then it's important to keep your style definitions in sync between your template file and the library. If your project is using the style library, you have a style in the library that has the same name as a style in your template, and those styles have different settings, then the definition in the library automatically overwrites the definition in the template each time it's used to start a new drawing (a warning dialog box is shown when this condition is detected).

The best way to ensure synchronization is to open your template file and run either the Update Styles tool (which pulls updates from the library) or the Save Styles To Style Library tool, depending on which way you want to transfer the styles. You can find both of these options and the Purge tool on the Manage tab.

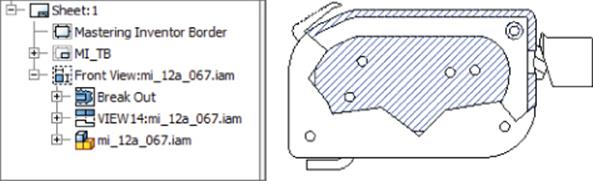

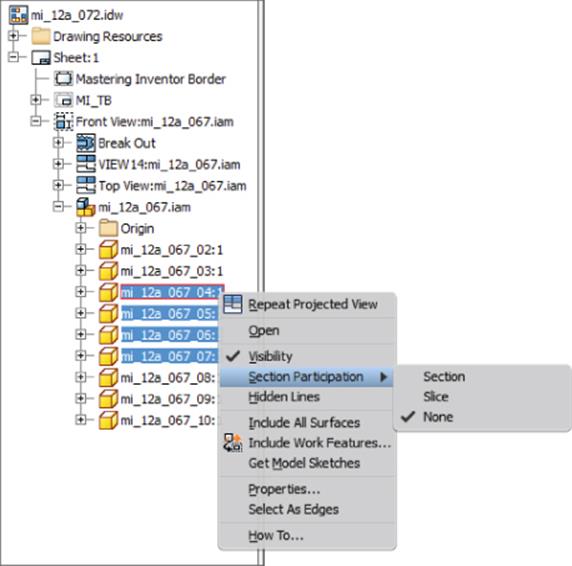

Creating Drawing Views

You will explore the various view-creation and editing tools in the following sections, which cover how to document different types of 3D models: part, assembly, sheet metal, weldment, and iPart/iAssembly.

Drawing views reference part, assembly, or presentation files. The workflows involved in creating and editing views from these different sources are similar, but with some notable exceptions detailed in the following sections.

Green Brackets and Raster Views

The Raster View option in the Drawing View dialog box creates a static raster-based view that approximates some view features. If this check box is selected, the computation of the view is quicker, but the view is less precise. Raster views can be used to speed up the drawings of large and complex general assemblies.

Green corner brackets around the drawing view are used to denote that a view is a raster view. Additionally, raster view browser nodes are marked with a red diagonal line through the browser node icon.

You can right-click a view in the graphics area or on a view's browser node to toggle it between precise and raster view methods. You can also right-click in the graphics area and select Make All Views Precise or select Make All Views Raster to toggle all the views from one method to the other.

Creating a Base View

Creating views in an Inventor drawing is an intuitive process. You'll start by creating some basic views of a part file while exploring the procedure and options along the way. Before you create any views, first open the part to become familiar with it:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_048.ipt in the Chapter 12 directory of your Mastering Inventor 2015 folder and click the Open button.

3. Spin the part around and take a look at it using the ViewCube® or the Orbit tool. Do not close the part.

4. On the Get Started tab, click the New button.

5. Select the Metric node from the list on the left and then choose the ANSI(mm).idw template from the Drawings section on the right.

6. On the Place Views tab, click the Base button to create a base view.

7. With the Drawing View dialog box open, move your mouse pointer around on the drawing, and you will see a dynamic preview of the part file. Do not click the screen just yet, or you will inadvertently place the drawing view.

8. Note that all open model files are listed in the File drop-down. You can select any open model file from the list or click the Browse button to select another file.

9. In the Scale input box, enter 2 or use the drop-down to select 2:1. You can specify scales in fractional or decimal formats (1/2 or 0.5 both work for half-scale).

10.Click the lightbulb button to turn on the View/Scale label.

11.In the View Identifier input, type Front.

12.In the Orientation pane on the right, click through the available options and watch the preview at your mouse pointer change. Select Top when you've finished. You'll note that although the orientation is called top, you have entered Front in the view identifier box. The orientation name can be considered a suggestion, and the word top will not show up anywhere but here.

Custom View Orientations

If the view you need to show does not exist in the Orientation pane, you can use the Change View Orientation button to step into the model and create any view orientation possible.

13.In the Style area, click just the middle button to create an unshaded view with no hidden lines. Note that the shaded button (blue) can be toggled on and off independently of the other two, but the hidden lines and no hidden lines buttons are mutually exclusive to one another.

14.Uncheck the Create Projected Views Immediately After Base View Creation check box, found in the lower-left corner.

15.Click anywhere on the page to create the view (or click the OK button).

Here are some tips for working with base views:

· Right-click any view and choose Open to open the model in a new window.

· Most of the options you see in the Drawing View dialog box can be altered later by editing the view, but it's important to set the orientation correctly originally because it cannot be changed once placed.

· To delete a view, simply hover your mouse pointer over it and then select the dotted view boundary, right-click, and choose Delete.

·

Right-click or double-click a view to edit it.

· Tangent edges and thread features that are not showing up in the view can be turned on by editing the view, selecting the Display Options tab, and selecting the respective boxes.

· Views can be moved by selecting the dotted view boundary that appears when hovering over them and dragging it into place.

· Clicking a line or lines in a view gives you control options for just those lines.

· Right-click lines, arcs, or circles and uncheck Visibility to hide those entities.

· Right-click the view and choose Show Hidden Lines to bring back lines that were hidden.

· Each base view created is listed in the browser; note the Base View button.

· Expanding the view node in the browser shows the model tree for that view where you can select all the edges of features at once. You can then right-click the selected objects on the page and toggle off the visibility, change the layer, and so on.

· To rotate a view, right-click it and choose Rotate; then select an edge to make horizontal or vertical, or use the drop-down to specify by angle.

· You can have as many base views as you need on a drawing, but the iProperties will be pulled from the first view placed.

· Views can be renamed in the browser or by editing.

· To display the view name without the scale for a single view, right-click View Label and choose Edit View Label; then remove <Scale> from the text box.

· You can suppress a view by right-clicking it and choosing Suppress.

Once you've explored the settings and edit options for the base view, you can close the file without saving changes and continue.

Set View Preferences in the Standard

You can set up view preferences for your company standard by accessing the Styles Editor, selecting Standard, and then selecting the View Preferences tab. This allows you to choose which properties to display or not display in the view label, set the First or Third Angle projection, and much more.

Creating Projected Views

Once a base view is created, you can quickly create other views based on it without having to specify the model again:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_049.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder and click the Open button.

3. Select the Projected button on the Place Views tab.

4. Click the base view.

5. As you drag your mouse pointer around the base view, notice the view previews that are being generated.

6. Drag straight to the right and click. You will see a rectangular bounding box indicating that a view will be placed there.

7. Drag straight up from the base view and click, again noting the preview.

8. Drag diagonally up and to the right from the base view and click.

9. Right-click and choose Create to generate the projected views.

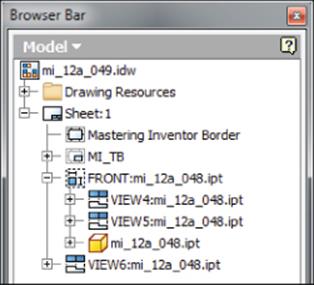

10.Expand the plus sign next to the Front view in the browser to see that the projected views are listed, as shown in Figure 12.6.

Figure 12.6 Drawing views in the browser

Here are some tips for working with projected views:

· Orthographic projected views are linked to the parent view in style and alignment and stacked below it in the browser tree.

· To break the style link between a projected view and its parent view, double-click to edit the projected view and deselect the Style From Base button in the lower right of the Drawing View dialog box. Then change the shading and hidden-line options as you like.

· Isometric views are not linked to the parent view in style and alignment and are listed separately in the browser tree.

· To break the alignment between a projected view and its parent view, right-click the projected view and choose Alignment![]() Break. A view arrow will be placed next to the parent view, and the projected view will be labeled to match.

Break. A view arrow will be placed next to the parent view, and the projected view will be labeled to match.

· To break the alignment without getting a view arrow, right-click the projected view and choose Rotate. You can set an already horizontal edge to be horizontal and still break the alignment.

· To reset the alignment, right-click the projected view and choose Alignment and then Horizontal or Vertical as appropriate. The projected view will move back into place. Choose In Position to link the projected view to the parent in its current position.

· By default, deleting a parent view or a base view will remove all projected views as well.

· To delete a parent view without removing the projected views, click the ![]() button in the Delete View dialog box, click Yes next to the views you want to keep and set them to No.

button in the Delete View dialog box, click Yes next to the views you want to keep and set them to No.

· Projected views can be created from views other than base views, such as detail views, section views, and even other projected views.

· You can select the parent view first and then issue the projected view tool, or you can issue the tool and then select the view. Either order is acceptable. If you have a view preselected accidentally and click the projected view button, that will be the view you are projecting.

· If you select the Create Projected Views Immediately After Base View Creation check box, found in the lower-left corner of the Base View creation dialog box, you can create base views and projected views at the same time.

· You can suppress a view by right-clicking it and choosing Suppress.

You can close the current file without saving changes and continue.

Moving and Copying Views

You can move drawing views between sheets by dragging and dropping the browser nodes. When a projected view is moved to a different sheet than its parent, a view arrow is generated automatically on the parent view.

To move a view, follow these steps:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_050.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder and click the Open button.

3. Expand the Front view node in the browser to show projected views 2 and 3.

4. Click the browser node of View2 and drag it down to the Sheet2 browser node.

5. Rest your mouse pointer over the top of the Sheet2 browser node icon and release the mouse button.

6. Sheet2 becomes active to show you where View2 has been moved. Notice that there is a browser icon for the Front view with an arrow and the sheet name in parentheses. This indicates it is linked to the parent view on Sheet1. Notice too that the moved view has been renamed.

7. Right-click the Front view icon in the Sheet2 browser and choose Go To to be returned to Sheet1.

8. Notice that a view arrow has been created next to the Front view.

To copy a view, follow these steps:

1. With mi_12a_050.idw still open, make sure you are on Sheet1.

2. Right-click View3 and choose Copy.

3. Right-click the browser node for Sheet2 and choose Paste.

4. Sheet2 becomes active to show you where the view has been copied to. Notice that the new view has been named with the next available view number.

Copying and moving views is often useful when you've detailed a complex view on one sheet and then have run out of space and need to expand the drawing to another sheet. Note that when you copy or move a view with dimensions or other annotations applied, the annotations are moved or copied as well. You can close the current file without saving changes and continue.

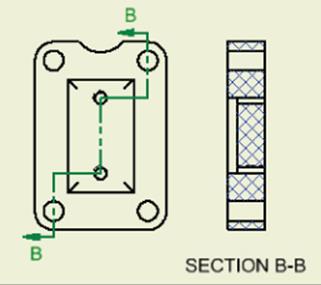

Creating Section Views

Section views are created by “sketching” a line across an existing view to define the section cut. The sketch is created automatically for you as you define the section line.

To create a section view, follow these steps:

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_051.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder and click the Open button.

3. On the Place Views tab, click the Section button.

4. Click the Front view to choose it as the view to be sectioned.

5. Hold down the Ctrl key and click to the left of the view. This ensures that you do not accidentally constrain the start point of your section line to any midpoints, center points, or endpoints.

6. Release the Ctrl key, drag the line across the part, and click to the right of the part, ensuring that you see either a perpendicular or horizontal constraint to indicate you are getting a straight line.

7. Right-click and choose Continue.

8. In the Section View dialog box, note that you can change the section identifier, scale, style, and section depth. You can also create a zero-depth section called a slice. Leave all these options at the defaults.

9. Drag your cursor above the original view, and notice how the placement is constrained perpendicularly to the section line.

10.Hold down the Ctrl key and click the screen to create and place the section view anywhere you like.

11.Click the section arrow and drag it up or down to see the section update automatically.

12.To align the section view with the base view, right-click the section view and choose Alignment and then Vertical.

13.Click the base view to specify it as the view to align the section to.

14.Click the section view boundary to see how the alignment works.

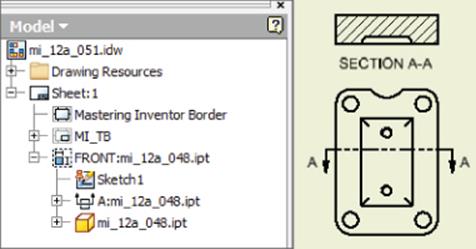

Look at the browser to see how the section view was added as a child view of the base. Also, notice the sketch that was created on the base view listed just above the section view node (Figure 12.7). This sketch is the section line itself and can be edited like any other sketch. You can add or remove constraints (including sketch dimensions) as needed to precisely position the section line around your base view. You do this by right-clicking the sketch in the browser and choosing Edit Sketch, just as you would any other sketch.

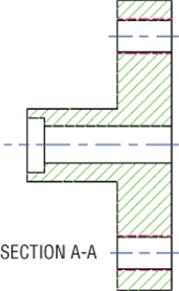

Figure 12.7 A part section view

Here are some tips for working with section views:

· Section line appearance is controlled by a layer and a style just like most other annotation objects. To determine which layer and style are used, switch to the Annotate tab and then click the section line. Note the Layer and View Annotation style in the Layer and Style drop-downs on the far right of the Annotate tab.

· Project a section view to create an isometric section.

· Orthographic section views are hatched automatically, but isometric sections are not.

· Edit or hide a hatch by right-clicking it.

· Display a hidden hatch or turn a hatch on for isometric section views by editing the view (right-click and select Edit View), selecting the Display Options tab, and selecting Hatching.

· You can hatch by material if you have mapped the materials and hatch patterns in your standard.

· Flip the section arrow direction by right-clicking the section line and choosing Reverse Direction.

· Show just the arrows of the section line by right-clicking the section line and choosing Show Entire Line.

· Edit the section depth by right-clicking the section line and choosing Edit Section Properties.

· To constrain a section line to the center of a hole, run your mouse over the hole to project the center point when you are creating the sketch line.

· When editing a section view, you click the Edit View Label button (it looks like a pencil). You can also use the Type drop-down and select View Label Properties. Then you can use the Property drop-down to add the parent sheet name or Index to your view label. This will place the parent view information in the view label for section views. This is often useful when the view resides on a different sheet.

You can close the current file without saving changes and continue.

You defined the section line on the fly during the previous exercise. Now you will bring in a sketch created in the part model and use it to create a section view. Figure 12.8 shows the sketched line in the model.

Figure 12.8 Section line sketch on model

Mapping Materials to Hatch Patterns

You can set up your template to use a predefined hatch pattern per the material of the sectioned part so that copper parts are hatched with one hatch pattern, mild steel parts are hatched with another, and so on:

1. Select the Styles And Standards panel of the Manage tab and click Styles Editor to open the Style And Standard Editor.

2. In the left pane, expand Standard and then click your standard.

3. In the right pane, click the Material Hatch Pattern Defaults tab.

4. Set the Default Hatch Style option for new materials added in the mapping.

5. Click the From File button to select a part file that contains all the material styles you want to import (set this up ahead of time), or use the From Style Library button.

6. For each imported material, click the Hatch Pattern field and select a new hatch pattern from the list. Use Ctrl or Shift to change several materials at the same time.

7. Click Save to save the changes to the current document; then click Done to close the dialog box.

To create a section from a model sketch, proceed with these steps. If you still have mi_12a_051.idw open, you can skip to step 3.

1. On the Get Started tab, click the Open button.

2. Browse for mi_12a_052.idw in the Chapter 12 directory of your Mastering Inventor 2015 folder and click the Open button.

3. Locate the sheet node in the browser and then click the plus symbol to expand it.

4. Expand the view node called Front to reveal the model.

5. Finally, expand the model node to reveal the part features.

6. On the part node (mi_12a_048.ipt), right-click and choose Get Model Sketches.

7. You will now see that a model sketch called Section Sketch:Model is present; right-click it and choose Include.

8. This will reveal a zigzag line on the part view.

9. On the Place Views tab, click the Section button.

10.Click any part of the included sketch, or click the sketch in the browser to use it as the section line.

11.In the Section View dialog box, click the Include Slice check box and then select the Slice The Whole Part check box to create a zero-depth section. Leave the other options at the defaults.

12.Drag your cursor to the right of the original view and click on-screen to create the section.

13.To change the section properties, right-click the section line and choose Edit Section Properties.

14.Deselect the Slice The Whole Part check box and the Include Slice check box to change the section to a full-depth section; then click the OK button.

15.Right-click the hatch and choose Edit; then click the Double check box.

16.Click the OK button to close the Edit Hatch Pattern dialog box.

Your section should look similar to Figure 12.9.

Figure 12.9 Section using model sketch

You can close the current file without saving changes and continue.

Import Hatch Patterns

You can load hatch patterns from an external PAT file to add custom hatch patterns to your drawings. To do this, edit a hatch and select Other from the Pattern list and then click Load. You can also do this in the Style And Standard Editor to add custom hatches to your company standard.

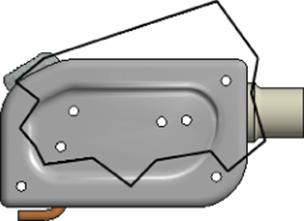

Slice Views

Slice views are simply zero-depth section views. They are often used to create cut profiles of complex surfaced parts such as automobile bodies, aircraft wings, boat hulls, and so on. A slice view is generated by creating a sketch associated with a source view and then using that sketch as the slice profile to create a slice section through a different target view. The slice is then executed on the selected target view. Slice views can be created on part views or assembly views.

To create a Slice operation defined by two existing views and sketch geometry, follow these general steps:

1. Select an existing view to use as the source view (the view you will sketch the slice onto).

2. From the Place Views tab, click the Create Sketch button.

3. Create sketch geometry to define an open profile to use for the slice.

4. Click the Finish Sketch button to exit the sketch.

5. From the Place Views tab, click the Slice button.