Eliminating Waste in Business: Run Lean, Boost Profitability (2014)

Chapter 8. Business Operations

Everyday Waste in Everyday Processes

Our business is about technology, yes. But it’s also about operations and customer relationships.

—Michael Dell

All businesses have core functions, which we have discussed throughout this book. Business operations are the functional areas where the product or service that the company sells is produced for the customer. Whether it is a product or component made by a manufacturer, consulting advice, a cheeseburger, or healthcare services, all businesses have operations. All businesses also have operational waste. People accept this everyday waste because they become numb to it. It doesn’t bother them when they walk by it every day. However, we have come to realize that the success of operations management comes down to managing the details. And every detail counts.

Like most people, we go to our primary care physician about twice per year. The person who manages the office has put decent processes in place so when we show up for our appointments, there is minimal wait. There is a process for when we go back to the examination room to ensure that little time is wasted getting our vital signs and finding out why we are at the doctor. (We have never waited more than five minutes in the exam room to see the doctor!) In the checkout process, efficiency in scheduling appointments and getting prescriptions is built into the process. Overall, it seems as if the operations manager has looked for ways to be efficient and effective.

However, you have to think about all the little areas of waste behind the scenes. A huge source of waste comes from the payment process. Like many people in the United States, we typically pay for things with a credit card. When the receptionist swipes our card, she prints out three 8.5 X 11 sheets of paper. Two pages go to us, which we recycle, and one goes to the office to file away. The office also eventually pays another company to hold the paper as a record for a couple of decades. You may be thinking that this is no big deal. A piece of paper is about five cents, and a black-and-white printed sheet is between 6 and 7 cents. So at best, this transaction is costing only 18 cents. Right?

Now consider that the group of doctors sees 500,000 people per year in the office across the 88 physicians. They all have the same credit card processing process. That equals $90,000 a year in paper costs. Now consider that as of October 2013, over 40,000 healthcare workers lost their jobs to save money.1 Now consider that there are about 209,000 primary care physicians practicing in the United States, with each physician seeing about 4,000 patient visits per year. If all of these offices have the same credit card processing practices, that means $150,480,000 is spent per year just for paper to process credit cards. If the average healthcare provider salary is $50,000 per year, that means over 3,000 of those workers could have kept their jobs with better business processes. Of course, there are a lot of reasonable assumptions in this example. Perhaps the jobs that were lost were themselves wasteful. But we include this simple example to illustrate how a small detail can build up to a large expense if not properly managed. Imagine how many small issues like this exist in every business. It is your duty as a leader to find these wastes and eliminate them. The small wastes very likely create more potential loss than the big ones.

Waste from Inefficient Workflows and Layouts

One of my friends, who is a Lean Six Sigma Master Blackbelt trained to identify waste, once told me a story about his visit to a local restaurant. He watched the servers in the restaurant trip over each other multiple times as they tried to deliver food and get drinks for customers. The drink machine was located next to the door to the kitchen so everyone had to go through the same three-foot gap to do all of the service. This bottleneck not only affected the efficiency of the restaurant, but was also a safety concern because of the likelihood that workers will run into each other and potentially cause an injury.

My friend looked at the layout of the workspace and actually drew an alternate workspace to give to his server as a recommendation for improvement. This happened about a year ago. There have been no changes. I wouldn’t expect the owner to change the area to my friend’s specifications, but I would have expected some change. The same scenario happens in all industries. We have seen offices that are safety hazards because of years of files and junk that’s never used.

Lean Manufacturing Tools

A handful of lean manufacturing tools can help almost every company gain a great deal of operational improvement. If you take time to utilize each tool, you will see how much waste you have.

The 5S Process

The first of these concepts is 5S, which enables you to get rid of all supplies, equipment, paperwork, and other things that are not needed. It’s like the TLC show Clean Sweep, but for business. Think about how much “stuff” you have in your office building that is never used. You might not think this is a big deal, but it is. This “stuff” takes up space, and space is always very expensive. It also gets in the way of efficient operations and can create safety hazards.

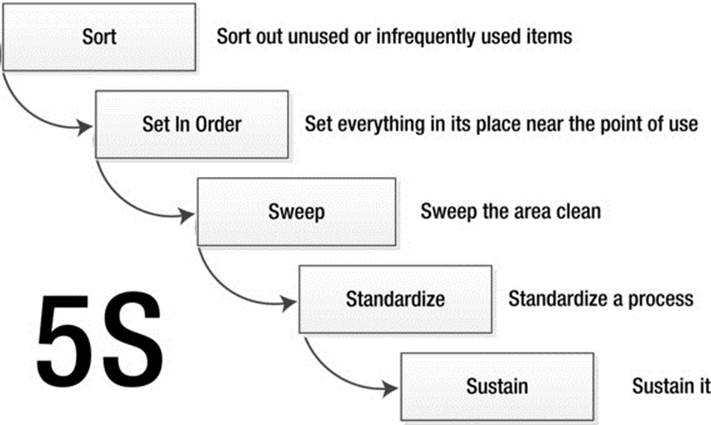

The first step in 5S is to sort out the items frequently used, the items not frequently used, and the items that are never used. The next step is to set the items in order by placing the frequently used items near the area that they are used. The infrequently used items are stored away from the work area. Other items are thrown away or donated. The third step is to sweep or shine the area by cleaning the work area or even painting it white to give it a clean look (this makes it easy to identify when it gets dirty). This sounds like a minimal change, but just the act of making something fresh and clean helps maintain the improvements. The fourth step includes creating and implementing a standardized process to maintain the new work area. The final step is to sustain the improvement by following up on it to ensure that it continues to meet the expectations set by the improvement. It is always easy to fall back into the same old behaviors. This is one of the reasons any improvement should have a conscious sustainment process embedded in it as well.

![]() Note Sort, set in order, sweep, standardize, and sustain all work areas. This process goes far beyond manufacturing facilities and can create major improvements in every area of business.

Note Sort, set in order, sweep, standardize, and sustain all work areas. This process goes far beyond manufacturing facilities and can create major improvements in every area of business.

5S is an easy process to implement and can help you make a safer, more efficient work environment with less potential damage to inventory. I have used this method in offices, manufacturing lines, storage areas for equipment or inventory, clinical workspaces, and even at a pharmacy. Overall, 5S will help you improve quality, safety, and workforce morale and can reduce changeover time, inventory costs, and process time, saving your organization both time and money.

There are numerous success stories about businesses that have implemented 5S. A metal fabrication company was able to increase inventory turnover by 67 percent, reduce inventory by 35 percent, and increase reliability of shipping time to 99 percent.2 In another example, a window manufacturing company was able to increase productivity by 35 percent and reduce overtime by 45 percent.3 It seems almost too simple that just the act of cleaning and organizing can reduce so much waste, but it is very real. Figure 8-1 shows the basic 5S process.

Figure 8-1. 5S Process

There are videos available online that show the effects of 5S. One in particular shows the use of 5S in an area as simple as an employee bathroom. There are pictures of what the room should look like. There are work instructions on how to clean the room after use. There is an audit and responsibility schedule that shows who is responsible for ensuring that cleanliness and organization is maintained. There are even inventory areas identified for cleaning supplies, with minimum and maximum quantities noted. 5S can be used almost anywhere.

The SMED Process

Another easy-to-use lean concept that will help with your workflow and layout is the concept of SMED, or Single Minute Exchange of Dies. This is the process of improving the time it takes to switch from making one item to making another. This concept got its roots from Shigeo Shingo in a steel fabrication factory, but is easily applied to many manufacturing, healthcare, or service industry operations.

The idea is to take activities that would be normally done while the equipment is not in use and convert them to being done without stopping the equipment. A simple example of SMED can be found in the activities to change a tire. I got in a minor car accident a few years ago. I was wearing my suit and had never changed a tire on my truck before. It took me 25 minutes to change the tire. Now consider Nascar. The tire change in Nascar takes about four seconds. There is a big difference between 25 minutes and four seconds. Pit crews have specially designed lug nuts and tools to remove the tire efficiently, there is a trained team who does the work, and everything is ready to go as soon as the stock car stops. The pit team utilizes the same techniques that Mr. Shingo developed. I have seen this technique reduce four or five hour changeovers into less than 30 minutes. The main benefits go back to 5S, which helps you analyze the workflow and layout to minimize wasteful motion or searching for tools. You also want to incorporate these methods with value-stream mapping (discussed in Chapter 4).

The Spaghetti Diagram

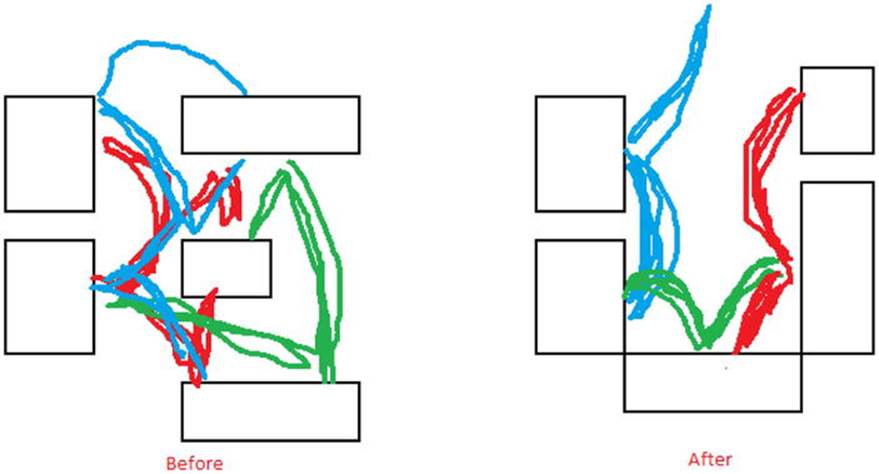

Although 5S and SMED help with layout issues that cause inefficiency and ineffectiveness, there is another tool—the spaghetti diagram—that you may use to implement these tools on its own or combine them with the other tools. Figure 8-2 shows an example of a spaghetti diagram. The lines represent three different people working in this area. The before picture shows excessive movement. By changing the layout and the job responsibilities, you can achieve the after layout and remove the wasteful movement.

Figure 8-2. Spaghetti Diagram

I have seen examples where the distance walked by employees is reduced by as much as 40 percent by using spaghetti diagrams to change the workflow and some work standardization. After some of my friends used these techniques, they have told me that they do simple things like prepare for the next day the night before so there is not as much to do in the morning or bring their coffee pot into the bedroom to reduce the walking distance. In our house, we pack all of the lunches for the family and set out the clothes for all of our children at night so that when we are getting everyone out the door in the morning, there is that much less work to do. There are simple things like having the drink station and bread warmer beside the salad station in restaurants, so that while a server is grabbing drinks and salads, she can also grab bread.

Something as simple as everyone using a centralized printer can create waste. This is because everyone has to run down the hall all day long. Poor layout design is a huge waste in most businesses, and you should be looking for these wastes around you. You might not think about where each employee’s footsteps go every day, but if you do, you can save a lot of money.

![]() Note Two of the eight wastes identified in lean operations are transportation and motion. Both of these wastes can be improved with a better layouts.

Note Two of the eight wastes identified in lean operations are transportation and motion. Both of these wastes can be improved with a better layouts.

Poorly Designed Facilities

Having the right facilities for the job can help you avoid waste. The waste in facilities comes in part from the assumption that you have to use facilities a certain way. For example, many MBA programs teach you about improving distribution operations by analyzing your customers and establishing your business near them. There is truth to this, but it is not an absolute rule in business. We talked in other areas of this book about tactics such as telecommuting as a way to reduce business expenses. With the technology that is available today, you should be pushing for employees to work from home whenever practical (with clear expectations around productivity, of course). Remember, most studies show that working from home is more productive. One Harvard study found that when a company instituted a work-from-home policy, the workers increased productivity by 13.5 percent. These home-bound workers also quit at a 50 percent lower rate than the workers in the office, and had much higher job satisfaction.4 (We discussed flextime and work at home time more in Chapter 5.)

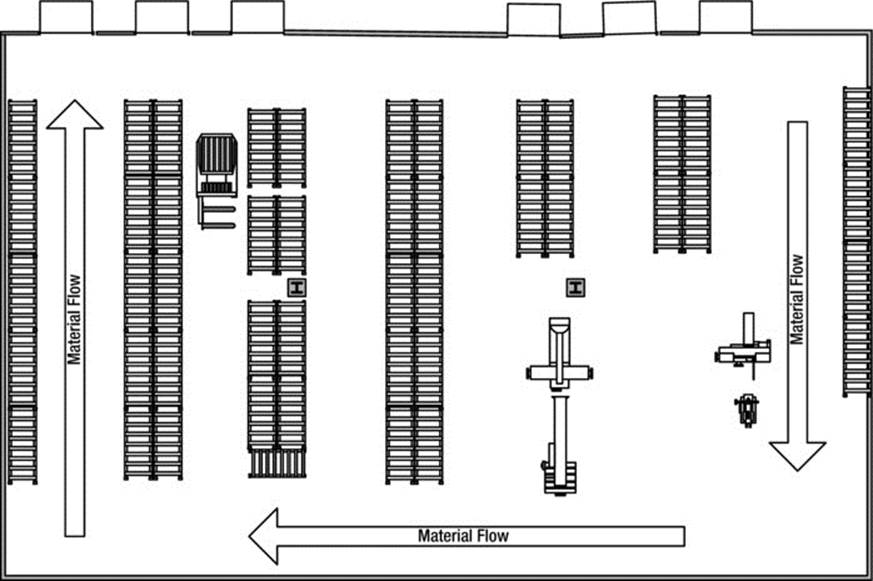

Another source of facility-level waste is the way that your facility is organized, beyond just where people walk and get the things they need. The facility should be designed to optimize material and product flow. Figure 8-3 shows a simple factory design where the raw materials are received on one side of the building; the materials are manufactured into a product and then shipped out of the other side of the building. Similar material flow can be designed into any work environment and lead to efficiency in the operations. This is a simple concept but I have been in dozens of factories that aren’t laid out in a way that makes material flow easy.

Figure 8-3. Factory Layout Example

![]() Note If your facility expenses are high, look for creative ways to reduce your facility needs.

Note If your facility expenses are high, look for creative ways to reduce your facility needs.

Over- or Under-serviced Equipment

Over the past 15 years we have worked with a variety of companies. Some choose to maintain their equipment very well while others choose to barely maintain their equipment at all. There is waste on both ends of the spectrum. Normally, the equipment manufacturers specify some maintenance requirements. When the equipment is under warranty, this should be the minimum requirement. Beyond that, how much you maintain your equipment depends upon a few factors.

How important is the quality of your product or service? If you rely on equipment to produce high-quality products or to test or measure something with a high level or precision and accuracy, then you should maintain your equipment as much as is necessary to ensure that it is performing well. You should also take the effort to test your equipment to ensure that your maintenance activities are successful.

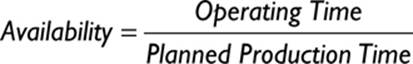

How important is it to keep your equipment running all of the time? If the cost of not having your equipment running is greater than the cost to fix it, then you must keep it from breaking down. You can measure the overall equipment effectiveness (OEE) to look at the maintenance and productivity of your equipment. In the metrics section at the end of this chapter, we show you the calculation for OEE. It is a function of the time that the equipment is running, the speed at which it’s running, and the quality level of your production. By maximizing OEE, you maximize the output of your equipment. You can also perform tests to predict equipment failures and proactively repair or replace components of the equipment to avoid downtime.

How expensive is the equipment? If the equipment is cheap enough, then it could be considered disposable. Look at the costs of maintaining the equipment versus replacing it frequently. Sometimes, it is cheaper to dispose of worn out equipment than it is to keep it running.

![]() Note Maintain your equipment to the level that you need to meet your business requirements. Under- or over-maintenance can cause waste.

Note Maintain your equipment to the level that you need to meet your business requirements. Under- or over-maintenance can cause waste.

Unnecessary Supplies and Services

The profitability of some types of businesses depends upon the supply expenses. Supply expense often includes inventory costs (discussed later in this chapter). One of the biggest wastes in the workplace is the use of paper—which we have mentioned in this book a few times—because it is so unnecessary.

Last year, we calculated the cost of the paper used in the school for each of our kids. We simply used an estimate of six cents per page and counted how many sheets of paper were sent home each day. We found that it would actually be cheaper to buy electronic tablets, such as iPads or Surfaces, and load them with software than to use all of that paper. If we had included the other costs that accompany paper, then the costs would have been much higher.

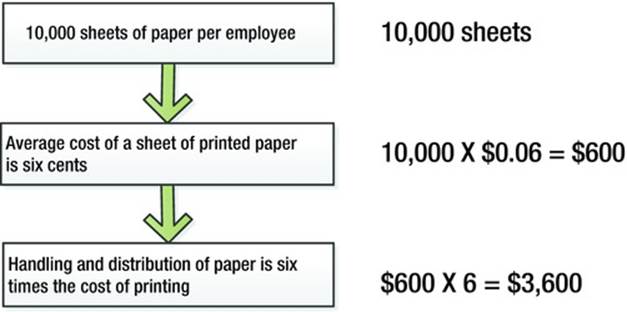

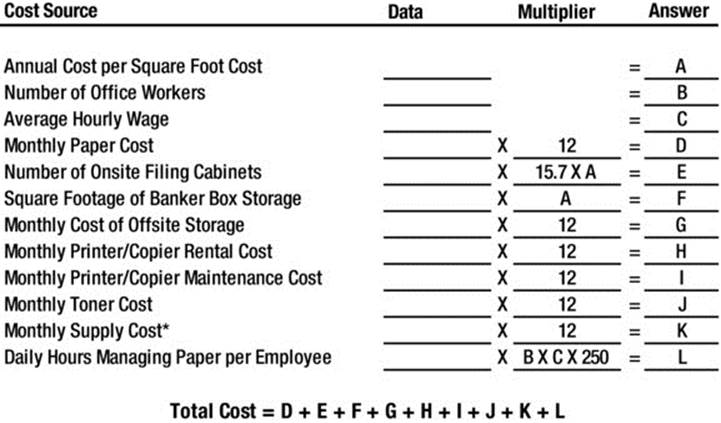

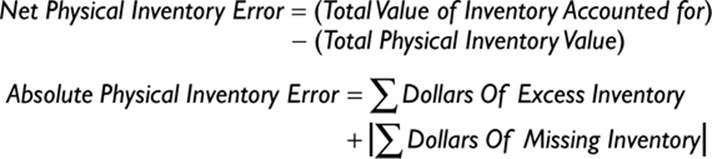

In the business world, the average office worker uses 10,000 sheets of paper per year.5 The costs of managing paper can be six times the cost of printing cost it. This means that the average office worker spends $3,600 per year due to paper use alone. Figure 8-4 shows the calculations used to come up with the $3,600 figure.

Figure 8-4. Paper Cost per Employee. (Source: Haggith Mandy, Paper Trails: From Trees to Trash—The True Cost of Paper, London: Virgin Books, 2009, pp 1-256)

We have all spent time in meetings watching packets of paper make their way around to the attendees while a presentation with the same information is projected on a screen. Or we have taken notes in our notepad only to review them later or copy them into a computer for safe storage. We cannot sit in the meeting with our iPad or laptop because it is considered rude since we might be doing something other than taking notes. So what do we do with all of those documents handed out in meetings? We write notes on them. Some of us doodle on them? Then, we either throw them away or put them in the confidential paper recycling bin. This is all waste. Of course, the cost of printed paper and its handling varies by business, and Figure 8-5 shows you how you can calculate these costs in your business.

Figure 8-5. Paper Cost Calculation Worksheet

Now imagine what you could do with that money besides using it to throw away paper. Why don’t you take advantage of this opportunity? In order to reduce paper costs, you need to change the way you think about business and operate your business. You need to leverage technology in order to drive these costs out of your business. You do this by using shared document storage areas and avoiding duplication of business documents.

Also, consider how many office supplies you can get rid of when you eliminate paper: paper clips, staples, staplers, pens, pencils, sticky notes, folders, filing cabinets, shelves, binders, binder clips, page protectors, and so on. Go to your local office supply store and look at the costs of these items. Without paper, you don’t need any of these. The space that you save can mean a smaller office space, which can improve your overall bottom line in addition to the basic paper and office supply costs.

Other supply costs include cleaning supplies such as trash bags. I have routinely seen janitorial staff take trash bags that are nearly empty and replace them on a daily basis. Now, because I do not use a large quantity of paper I generate a full trash can probably once every three to four weeks. So instead of one bag being used, 15 to 20 bags are being used. This is only $9 per year in material cost loss, but consider if this is done in a company with 1,000 employees. That is $9,000 per year. You may think that $9,000 per year is not a lot, but remember that this is only one small example. These small examples exist all around us and add up to significant expenses.

There are other supplies that are totally unnecessary: Styrofoam coffee cups, napkins, forks and other eating utensils that should be provided by the employee.

Then you need to think about all the possibly unnecessary services. At my place of employment, about 10 years ago, we went from having many janitors that were on staff 24/7 to having one. Each department has their own vacuum cleaner, bottle of spray cleaner, and rags. When each of us feels our office is a little dirty, we clean it ourselves. On the surface it seems like a bad decision (when you look at the hourly rate a professor makes vs. the hourly rate of a janitor), but faculty offices simply do not need cleaned daily. Really, at the amount they are used, they don’t even need it monthly.

Some companies also pay for extremely wasteful services such as landscaping. If you use native, perennial plants and trees, you will not only save on landscaping, but also save on utilities. Native plants means possibly no watering needs, and native trees lower heating and cooling costs. We suggest you look around at all the services you are using to see what is really necessary.

![]() Note Look at the routine operations supply and services costs and make sure that you still need to use those expenses. There is a lot of waste in paper.

Note Look at the routine operations supply and services costs and make sure that you still need to use those expenses. There is a lot of waste in paper.

Excessive Overhead Costs

There are lots of ways to cut down on overhead costs. With energy costs increasing, this can be a priority for many businesses. Manufacturers are large users of both electricity and fossil fuels. This is not a complex process. If you do the analysis on what it takes to cut energy costs, there is often a short payback when you make energy efficient changes. You can undertake large projects like changing out all of the lighting fixtures in your company or replacing natural gas burners. Depending upon the individual energy use of your company, these may be “no brainers.”

Almost any company can justify the simple things to reduce energy costs. Installing motion detector lights and automatic and low-flow faucets are low-cost improvements that even smaller companies can undertake. An even lower-cost alternative is encouraging employees to turn computers off when they leave work or turning the lights off when they aren’t needed. (Or, once again, introduce work-from-home policies.)

You can reduce your utility use by adjusting the thermostat up or down, depending on the season. (Of course, if you choose to do these things, you may negate any improvements if employees bring in space heaters or fans.) We had a horrible heat wave a couple summers ago, and some businesses instituted a four, 10-hour-day work schedule to keep their cooling costs down. This coincided with the first time gas spiked over $4.00 a gallon, so workers were happy to save on gas as well. For any improvement, you also need to look at the potential effect on employee productivity. You don’t want your employees so uncomfortable or tired that they cannot work.

Another utility you can reduce is your phone service. You can utilize the voiceover Internet protocol (VOIP) instead of the standard telephone service to reduce your telephone costs. There is enough competition in this sector now that VOIP often makes more sense than using land lines. You should also consider whether your employees still even need phones. So much business is done through e-mail now, and many employees never use their desk phones. When they do make calls, they frequently use their cell phones. You are very likely paying for phone services that are not being used.

Although we are sure that large companies in part go after sustainability initiatives to be environmentally responsible, the main reason why they have adopted these practices is because they lower their costs. There are potentially thousands of dollars in lost revenue that could be gained by selling your recyclable materials rather than throwing them in the trash. Companies will pay you to come remove these materials from your facility, rather than you paying a trash company to remove them. The only effort that is necessary to take advantage of this opportunity is the time it takes to separate your trash according to type. You can also look for ways to recycle your own materials, limit your packaging materials, or purchase materials or packaging with recycled content. This is so simple to do. If you don’t adopt some kind of internal recycle and reuse processes, you are throwing money away.

![]() Note Save money and boost your company’s reputation at the same time by becoming environmentally friendly.

Note Save money and boost your company’s reputation at the same time by becoming environmentally friendly.

Further, you should eliminate unnecessary entitlement costs. I can’t count how many trade shows and conferences I have attended over the years. The majority of the time I spent at these events was wasteful. Now, that is not always the case—we discussed trade show benefits in the Chapter 4. There are other benefits such as educational opportunities. The point is that you need to look at each of these expenses and determine if there is a real return on investment.

You should also look for fixed costs, such as facilities, that can be eliminated. If you improve your operations in other facilities and use the available capacity to produce more products. Incorporating the inventory-reduction techniques that we talked about earlier may eliminate the need to have as many warehouse locations or allow you to reduce the size of your building. Work-from-home policies may eliminate the need for office space and office furniture.

You can also review all monthly or annual business dues, memberships, and subscriptions. If there is a true business benefit of these costs, they may be a good investment. Often they are just for personal enjoyment or to boost resumes. Many people sign up for LinkedIn premium or other similar sites and don’t use them. I have worked in companies where one employee will get a subscription to a trade magazine and then pass it around to others. This is a simple way to keep subscription costs low while still providing benefit to all. If a database or publication is necessary to research the industry, then keep it, by all means, but don’t be wasteful about such purchases.

Also, look at your company certifications. Certifications such as ISO 9001, TS16949, or AS 9100 often have a customer requirement tied to them. This means that because your customer wants you to have these certifications, you must have them in order to do business. One huge waste in quality-management systems certifications is getting them just because your customers ask you to. There can be real business efficiency and effectiveness gains from properly implementing these systems and using them as a foundation for your continuous improvement, supplier control, and quality control. But if your goal is to get a flag to hang in front of your building, then you are getting certifications for the wrong reason. If there is no process improvement from a certification and your customers don’t care about the certification, then why are you doing it? We have seen companies spend tens or hundreds of thousands of dollars to get a certification that provides no real benefit, other than bragging rights. You should avoid these types of certifications. You need to identify all certifications you currently have, look at their costs and benefits, and then eliminate those without significant value.

![]() Note There are lots of ways to control overhead. Challenge every expense and determine if it is necessary.

Note There are lots of ways to control overhead. Challenge every expense and determine if it is necessary.

Waste in the Product Development Process

Many businesses thrive on product or service development. Manufacturers develop products for sale in order to maintain their current size or grow the business. Service providers develop new services that customers want in order to do the same. If product development is so important, then why don’t we do it well? To be fair, many companies develop products well, but the majority of companies don’t. We drive waste into our businesses by doing a poor job of developing products. We discuss product development and market research in Chapter 3. Here we cover a few operational sources of waste in the process that many people don’t think about.

Customer Requirements

As we began to discuss in Chapter 3 on marketing, misunderstanding or not taking the time to ask the customers what they want is a major driver of waste in the product development process. You obviously need to conduct and interpret proper market research. Having no or bad research can lead to building a facility to take care of customer needs that don’t need to be filled or developing a product or service that doesn’t sell. Just look at how many restaurants fail. Look at the products that are sold at closeout stores like Big Lots to see examples of not understanding customer requirements.

There are other issues around understanding customer requirements. In Chapter 4, we talked about the waste driven in sales. One major sales waste is not considering your sales job, engineering job, or customer service job as a job of gathering customer requirements. I have seen this multiple times in my career, where a custom manufacturer sells its services to a larger company without understanding the requirements of that company. These requirements may include open capacity, technical knowledge, quality control, specialized manufacturing processes, or even electronic communication for order fulfillment. If you don’t understand these requirements up front, then you are likely to incur costs that you didn’t budget on the project—if you are able to meet the requirements at all. If you cannot meet the requirements, you will probably lose the sales and never get another chance to get them back. You cannot assume that the way you have always done business will work for every customer. If you are not willing to do the work of gathering customer requirements and ensuring your capability to meet them, you are better off not getting the sale.

In my days of providing components to automotive suppliers, I developed price estimates for thousands of items. I quoted an item about 10 years ago at a price of around 40 cents. The buyer at my customer’s business had two competitive quotations between 10 and 15 cents. Obviously, I did not get the sale on this part. I talked with the buyer and explained some technical issues with the part that would make it expensive to make and would drive the need for increased quality inspection. I knew my customer and knew what the requirements would be. Later, I found out that my customer was unsuccessful with the item using the cheapest supplier. With the second supplier, the costs ended up being close to what I had estimated after weeks of delay due to product development issues. This was a case where I felt good about the service that I gave to this customer. This, along with many other examples, built trust between this customer and my company that led to profitable growth using our capabilities as a manufacturer. You will save and make money long-term by understanding the customer’s requirements, providing a quality product, and pricing appropriately.

![]() Note You will save and make money long-term by understanding the customer’s requirements, providing a quality product, and pricing appropriately.

Note You will save and make money long-term by understanding the customer’s requirements, providing a quality product, and pricing appropriately.

Planning for Production

After gathering customer requirements, companies also tend to overpromise on delivery expectations. Still others frustrate their customers because they don’t commit to deadlines that are aggressive enough. A primary reason for the variability in delivering on promises is that in the development cycle, the production or service operations are involved after the deadlines are established. Production personnel absolutely should be involved in establishing deadlines. This simple process can avoid product development waste by ensuring that promises are kept. Huge waste is created because sales and development departments don’t talk to each other.

Customer Maintenance

I often tell a story of how we fired the third largest customer of the company where I worked as an example of how volume isn’t the largest driver of profitability. When the company where I worked made the choice to eliminate this customer, its profitability almost immediately increased. The expense of taking care of all of this customer’s service requirements exceeded the contribution to overhead. We were using profits made on other customers to subsidize this customer.

Not all customers are created equal. Not all customers are a good fit for your business. As we discussed in Chapter 4, you must know the CLV (Customer Lifetime Value) of each customer. If you have a mutually beneficial customer and supplier relationship, then you need to manage it. This includes ensuring that you continue to understand the requirements and your ability to meet them. In the product development cycle, you need to maintain your relationship with your customer to make sure that you are pursuing the right technology advancements to service your customer needs.

![]() Note Not all business is good business. Not all customers are good customers. You need to maintain your relationships with your good customers and not spend all of your time courting new ones.

Note Not all business is good business. Not all customers are good customers. You need to maintain your relationships with your good customers and not spend all of your time courting new ones.

Waste in the Supply Chain

There are three major cost components to any business: labor, overhead, and materials. The distribution of these costs in any business varies depending upon the industry. Supply chain management includes the activities associated with the materials portion of this equation. Manufacturing companies have the largest percentage of cost from materials. Service companies, like restaurants and healthcare, have lower percentage of cost from supplies, but the costs are still significant. There are many places where supply chain operations can go wrong.

Managing Inventory Levels

One of the eight wastes identified in Lean Manufacturing is with inventory. In my days in the restaurant industry, I remember taking over the job of a Bar Buyer for a large restaurant. Unfortunately, I had taken over this job due to someone’s sudden death, so I had no guidance to begin the job. There were very few records—another bad thing in the world of inventory control. I walked into the liquor storage room and just began to look around. I quickly realized that over half the bottles were covered in dust. This was an extremely busy restaurant with an extremely busy bar. We had as much as a two-hour wait every night, so the entire lounge area was full almost all the time. So why were there so many dusty bottles? I could go through many problems here: not using FIFO (first in first out), severe over-ordering, and ordering exotic liquors that were rarely used. The point here is that everywhere you carry inventory, even if it’s just one stockroom of liquor, needs assessment.

Excessive inventory is wasteful because it can lead to obsolescence or product damage. Inventory also takes up space in your facilities, which keeps you from using that space for something productive. Inventory ties up your cash so it cannot be used for other purposes. Inventory’s greatest waste is that it helps hide other issues in your operations or the supply chain. This is why “world class” companies work hard to minimize inventory. But sometimes inventory is a good thing because you have identified issues that you cannot control. If you have minimum order quantities, unreliable suppliers, or unpredictable customer orders, you should plan on having inventory to hide these problems. So even though having too much inventory is a waste, not having enough inventory can also be a waste.

Regardless of how much inventory you keep on hand, you should locate some of your inventory close to where it is being used. You should only locate a finite amount of the inventory here, because too much inventory will get in your way.

![]() Note Make sure that your inventory levels are the right size and that an appropriate amount of inventory is stored near the work area.

Note Make sure that your inventory levels are the right size and that an appropriate amount of inventory is stored near the work area.

During my career, I have witnessed various ways of managing inventory. One way to manage inventory is to review economic order quantities. This process looks at the costs associated with a purchase, including price, shipping, processing, and storage costs. You use this to figure out the lowest total cost for your inventory. This is a great idea in theory, but it can leave you holding onto inventory you don’t need and may make you increase your warehouse space to accommodate the inventory because your inventory levels aren’t based on your customer needs. Basing your inventory on purchase and shipping costs may drive you to buy inventory that you may never use.

Another method to manage inventory is by using a bin system and an electronic scanner. The “bins” are the locations in the warehouse. The scanners are like the ones you see at the grocery store. This bin system helps you maximize space utilization by allowing any inventory item to go anywhere in the warehouse since you are telling your computer system where items are stored rather than maintaining locations specifically designed for items. This makes sense in some cases because of the space efficiency it offers. The other wastes, such as searching or transportation caused by this method, may be less than not maximizing your space utilization. In other businesses, the workflow is more important than the space utilization. You need to look at your own business to determine what is most important to you.

Another inventory management system is the Kanban system. In this system, you calculate the inventory buffer you need to ensure that you do not run out of inventory in operations. Then you order materials only when you reach your minimum inventory level. You then receive new inventory shortly before you run out of inventory. This is a great way to keep your inventory costs low, but you may pay more for the materials due to the smaller, more frequently needed order sizes.

Using the material requirements planning (MRP) method is very common as well. This is where you look at open orders or forecasts and order components in the quantities that are necessary to meet those requirements. This could leave you with inventory that you don’t need if your forecasts aren’t accurate or your customer orders fluctuate. Additionally, MRP relies upon production schedules and bills of materials (the recipe for the item) to be correct. Bills of material must be correct in any operation for accounting purposes but production schedules can change daily due to a variety of factors. MRP processes can drive up your inventory costs and leave you holding onto inventory that you may not use.

Consignment is another method that is used in inventory management. This is where you don’t own the inventory until you use it. The materials are in your warehouse, but they belong to your supplier. You tell your supplier when you use the materials and pay for them at that point. This method of communication to the supplier may be through your own warehouse management system, a system supplied by your supplier, or a manual audit performed by your supplier. The downside to this method is that although you don’t take ownership of the inventory, you take responsibility for it. You may also have to commit to some minimum use of inventory prior to entering into the deal. There is often some level of exclusivity that the supplier may expect as part of the deal. With exclusivity, there is a potential for abuse on pricing or other service costs. Consignment deals are great. But you need to be smart about how they are structured or they can drive waste.

Regardless of what the experts selling you software or hardware tell you, the best processes for inventory management are the ones that put the control of managing inventory as close to the user of the inventory as possible. Small and midsized businesses with only a few dozen or a few hundred inventory items don’t need special software to manage inventory. A well designed spreadsheet to identify inventory needs and a Kanban system or visual signal to tell users to order material are the only tools that you need. Sometimes a pure Kanban system won’t work well because of the issues mentioned earlier. You can get creative and work deals with suppliers that allow you to bundle different items to get volume discounts. You may also want to use a combination of the other tactics we mentioned earlier. Normally, the best solution is the one that uses the right tool for each situation.

If you have a larger company, there is no way to avoid using a MRP system to help you identify your material needs, but you can still use a combination of consignment and Kanban methods to minimize your inventory costs. Large manufacturers who utilize Lean manufacturing methodshave been known to locate supplier facilities within a few hours of their facility to make daily shipments of materials easier. Using this combination allows companies like Toyota to use MRP to manage inventories but also keep only a few days of inventory on hand.

![]() Note There is no single way to manage inventory that works for everyone. Fancy software is not necessary most of the time.

Note There is no single way to manage inventory that works for everyone. Fancy software is not necessary most of the time.

Managing Your Warehouse

Much like the process of managing your inventory levels, there is no one-size-fits-all way to run a warehouse. For operations with relatively low demand for supplies, a fixed location system where each supply has a home may be more appropriate than the bin-and-scanner method mentioned earlier. The waste in managing your warehouse generally comes from a combination of not doing some basic warehouse-management activities and from assuming that you should do it the same way as another company.

Just the Basics

If you are not doing some basic activities to manage your warehouse you should consider changing your processes. For instance, when you received components from suppliers, you should only have one unique component per box. We are not saying for instance that if you buy hamburger buns that you should only have one bun per box. What we are saying is that you should not mix your hot dog buns, hamburger buns, and napkins in the same box. If you receive multiple items in the same box, your warehouse workers have to separate them so they can be used. This may seem like a simple concept, but we have seen experienced warehouse leaders who didn’t do this.

Along the same lines, you should have a maximum number of different types of items on a single pallet or skid. This is mainly important for companies that have a warehouse. Smaller companies may not buy items in enough bulk to be able to get skids full of supplies with only a few unique items on the skid. The efficiency lost in breaking down or separating the unique items sent on single skid or in a single box is substantial for larger warehouses.

Furthermore, you should have standard package sizes and quantities. For instance, every time you order hamburger buns, you should order 100 of them and they should come in the same size box every time. A key element of any warehouse management is standardization. Set yourself up for success requesting standardization from your suppliers.

Whether you have a single unique item on a pallet or multiple items, you should have your supplier label each pallet. This helps eliminate waste in figuring out what is on each pallet, making receiving of materials more efficient and effective. You should also standardize the labeling of your items. This includes the label format and location. By doing this, you know where your labels are on the boxes and you ensure that you are able to read or scan the label using barcode scanning.

If you are running a warehouse, you need to plan your space to maximize your effectiveness. Simple specifications around the size of the pallet that you receive from suppliers can help you optimize the storage locations. Most suppliers will meet your expectations, although there may be some extra expense associated with the request if you are asking for expensive materials. The size is not limited to just the pallet but also how your purchased supplies are stored. If you have storage racks, you need to make sure that your materials will fit in your racks. Again, this may seem basic, but many hours have been spent in warehouses repacking pallets from suppliers so that they would fit onto the storage racks.

You need to ensure your warehouse is optimized. Some warehouse managers choose to receive inventory into an area where the items are inspected and prepared to be put into the warehouse. If you set up standards with your suppliers, then you can eliminate this wasteful activity by receiving items directly into your warehouse and having any quality checks that are necessary concurrently with the receipt.

![]() Note Minimize the waste in your warehouse operations by having standards in place. Your suppliers should be willing to help you with your standardization needs.

Note Minimize the waste in your warehouse operations by having standards in place. Your suppliers should be willing to help you with your standardization needs.

Movement or searching within the warehouse is a tremendous waste. I have personally spent hours in warehouses looking for items because the warehouse was not well organized. Whatever your organization method is, it should be clear and consistent. Your organization method should be simple enough that you can find things manually without a fancy system. As your warehouse management matures, you may decide to use fancier systems to maximize your space utilization, such as a bin system that allows you more flexibility on where you store items. I challenge you even at that point to try to keep some logic in your organization. Remember that if you can’t make a process work manually and on paper, introducing an automated system will not make your processes any better. As we discussed in Chapter 6, you have to stop thinking about software as a solution and fix the basic processes first. Be organized and efficient.

![]() Note Automation will not make a bad manual process any better. Organize first and automate later if needed.

Note Automation will not make a bad manual process any better. Organize first and automate later if needed.

Your Processes

Some warehouses operate through visual cues while others depend upon reports. The ones that depend on reports don’t perform most warehouse activities unless there is a report that triggers them. The ones that use visual cues allow the warehouse workers to do the routine tasks needed to manage the warehouse based upon those cues. I have seen both methods work, but your processes should focus on execution of activities and your customers, instead of what you think is most efficient for your workers. Your customers want you to deliver your inventory to them in the most convenient manner possible. If any of your activities jeopardizes this, then you are generating waste by creating unhappy customers.

If you are counting on reports to tell you what to do within your warehouse, you should look for ways to use visual cues to tell you when to do an activity. For instance, if a supply is supposed to be stored in a location for use by your operation, it should be understood that when that supply gets below a certain level or depleted, someone is responsible for filling the location with new supplies. This is like the soda racks in a convenience store. There are slopes racks that always keep the inventory at the front of the shelf. The worker loads the soda from the back of the shelf to fill the available space. When I was in college, one of my jobs was to sell beer and malt beverages in a small shop attached to a bar in Pennsylvania. I went into each cooler, looked for shelf space that was not filled with inventory, and filled it with bottles of beer from cardboard cases stored within the cooler. I didn’t have a report that told me that I needed to load a six pack of Molson Ice, a case of Woodchuck Hard Cider, and a few bottles of Bud Light onto the shelves. My eyes told me that I needed to do that work. Some warehouses become far too dependent upon reports and don’t use the simple method of checking.

If you choose to have a dedicated receiving area rather than put all items directly into inventory, it should be understood that the receiving area is cleared before the end of the shift. Reports aren’t necessary to tell the warehouse worker that there are items in the receiving area. Reports are necessary to alert workers to pull items if visual management is not in place or to send items to customers. Unless it involves an order to pull inventory for use, look for ways to get rid of the report-based process.

Your warehouse processes must be customer focused. This is true whether the customer is a third party buying items from your company or is another department in your company. Activities requested or needed by customers should always have priority. I couldn’t believe the first time I saw a “kill or fill” order fulfillment process. This is when a request for inventory comes to the warehouse and triggers the warehouse to send inventory to a customer. If there is available inventory on hand then there is no problem. The warehouse fills the order. If there is no available inventory on hand, then the order is “killed,” or not filled without any notice to the person who requested the item.

Needless to say, this process is used only with internal customers; if this process were used with external customers, you would not have customers for very long. The point is that this lack of customer service in a supply operation should never be accepted. At the very least, if a supply is not on hand, the customer should be notified with options such as a back order (a delayed order) or a replacement item. Any other process, although it may not cost the warehouse anything, costs the business dearly because a user of supplies is expecting them and doesn’t get them. Even worse, the customer gets accustomed to this egregious lack of service and wastes precious time reordering items because they did not get the items the first time. This is another instance where departments should talk to each other. Sales should also know what is going on in terms of inventory.

Shipping

Companies frequently don’t realize how much money is wasted due to poor planning. Expedited shipping costs are a large waste in many businesses. These can be avoided by eliminating common traps like delayed decision making or not managing your capacity well enough. These are the common root causes of high shipping costs.

You should spend time figuring out the best shipping methods for your company and negotiating fair rates. After you have done this, try to drive your overnight shipping costs to zero. This concept applies to the goods you ship to your customers as well. All logistics companies are in competition with each other and are happy to negotiate with you for better rates.

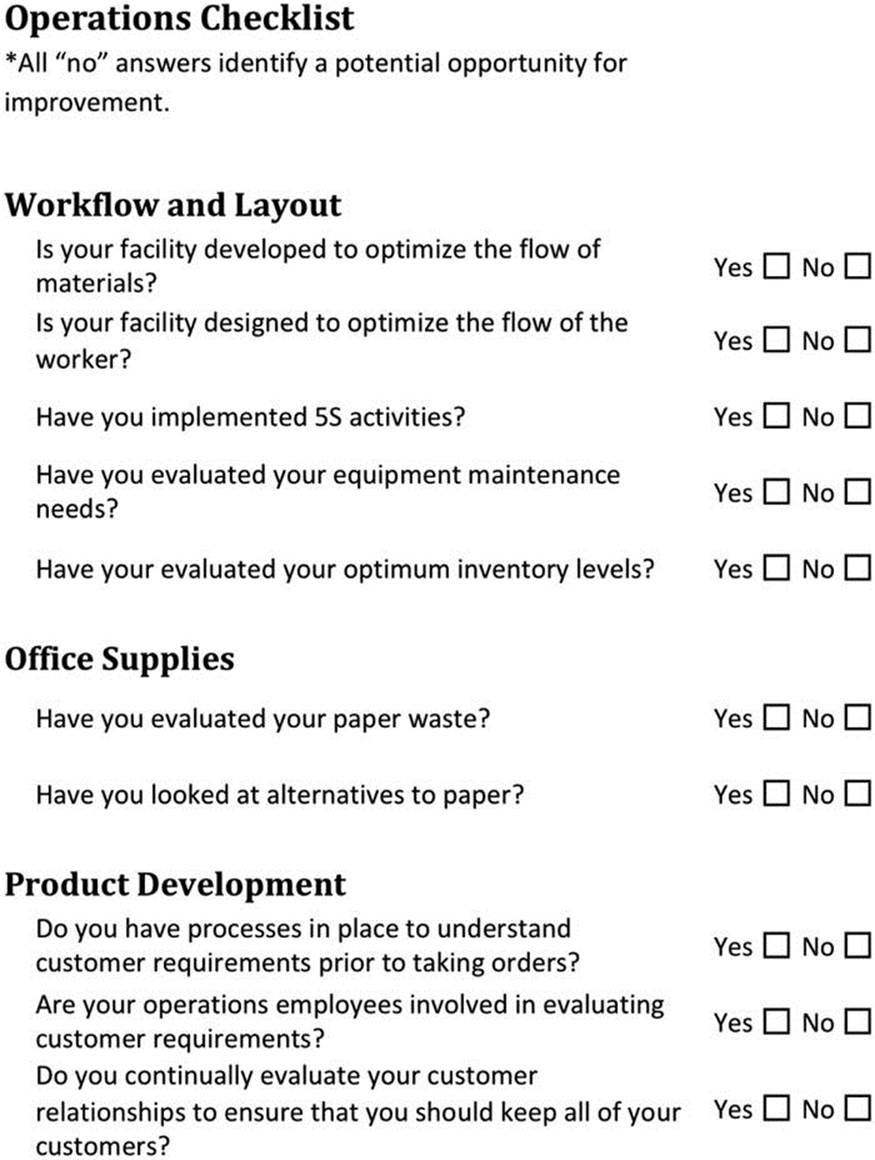

Vendor Management

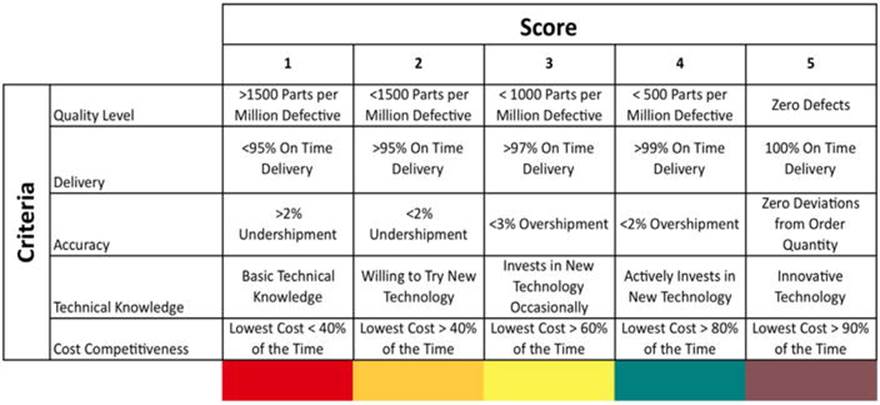

We have talked a good deal about vendor management in regard to a warehouse. There are other considerations in regard to vendor or supplier management to avoid waste. For one, if the supplier supplies an item or service that is important to your product or service, you must evaluate that supplier to ensure that you get consistent quality and service. We have always supported developing long-term relationships with a few key suppliers, but it is frankly naïve to trust that your supplier is doing everything you need them to do. You should ensure that your supplier is delivering on time. Is he giving you consistent quality? Does the supplier follow through on promises? Are there technical skills or processes that you need that your supplier provides? If not, are they working on developing those skills or processes? Figure 8-6 shows an example of some criteria that you can use to evaluate your suppliers. The actual criteria that you use will vary depending upon your business needs, but the point is that where possible, you should develop objective criteria to measure your suppliers.

Figure 8-6. Supplier Ranking Criteria

Once you have developed and communicated the evaluation criteria, you can compute a weighted score. For instance, you may value quality, accuracy, and delivery more than the other criteria, so you give quality a weight of 30 percent, delivery and accuracy 25 percent, and the other two 10 percent. So your evaluation may look like the following:

![]()

By giving each supplier a rating on each category, you can come up with a composite score. This score should influence purchasing decisions so the better performing suppliers are more likely to grow with you.

It is a good idea to ensure that you maintain a supplier manual to communicate your expectations to your suppliers. Failure to do this can lead to waste in areas where you depend upon your suppliers. In this manual you should cover various topics such as quality planning, product approval, certification requirements, quality control, problem solving, deviations from standards, and the performance rating system noted in Figure 8-6.

Companies either make the mistake of not doing this or they create manuals so complex that it is absolutely impossible for anyone to comply with the requirements. This is similar to a company policy and procedure manual that includes hundreds of pages of information that “every employee must know.” This tactic of over-documenting requirements only creates red tape and slows processes. Much like your own quality and policy manuals, supplier manuals must be simple and only cover important points so they will be utilized.

![]() Note Your suppliers are your partners. They want to make you happy to keep selling their products. Work with them to minimize your costs.

Note Your suppliers are your partners. They want to make you happy to keep selling their products. Work with them to minimize your costs.

Purchasing Policies

Purchasing functions can often make or break the profitability of a company. This is especially true in manufacturing organizations with very high material costs. I once worked for a company that spent $30 to $50 per pound for a plastic material used in a process. Fluctuations in the material prices greatly influenced our overall costs. Vendor management is often done by the purchasing team so the purchasing team has a large influence over the quality of the supplied items. Companies often put in smart policies to avoid conflict of interest and govern how business is conducted. It would be a bad practice to allow purchasing decision-makers to accept kickbacks or gifts from suppliers. It would also be a bad practice to purchase items from family members or family-owned companies. You should have simple policies to avoid these types of unethical practices.

One of the most wasteful purchasing policies is looking for the lowest price. Now why do we say that the lowest price is bad? We are not saying that the lowest price is bad. Often the lowest price can be from the best quality supplier with the best service. More often, however, purchasers shop for the lowest price even though there are some quality, delivery, or service failures as a result. Your purchasing policies must be based on the total cost of purchasing. These costs include the ease of use of the products on the manufacturing floor, in the kitchen, on the nursing unit, or wherever those products are used. Another part of the total cost that is often ignored is the chaos caused by unpredictable service, quality, and delivery.

We have seen many times where the purchasing department is part of the finance team. The logic to do this is pretty good, right? Purchasing departments are supposed to control costs. Operations is a more appropriate place for purchasing departments. This is due to the need for the operations to use the purchased items. If the same person who is responsible for using the materials is responsible for keeping the costs low, you are likely to get the best balance of total cost. No chief operations officer worth his salt will allow the efficiency of his labor or quality of his product suffer because of cheaper materials. He also will not spend too much on materials with a limited return on efficiency or quality.

Another issue is supplier relationships. If you are requiring your suppliers to commit resources and technology to you, you should also commit to having a long-term relationship with those suppliers. It is not only the best thing for the supplier, but it also helps control your costs. As long as you have put in place a couple of competitive suppliers for key items to keep everyone honest, then the long-term relationship is based on trust and knowledge of customer needs. Having a committed group of suppliers who feel attached to your company eliminates the waste of monitoring multiple suppliers to ensure that they are doing the right thing. It eliminates the need to explain your standards every time you develop a new product. It eliminates the back and forth negotiation of deviations from standards because the supplier understands the questions to ask to ensure that he knows exactly what is important. We have seen both types of purchasing organizations. The overly cost-sensitive companies end up paying more in the long run. The companies with no supplier controls in place end up getting manipulated by the suppliers. There is a balance of fair pricing and respect for expectations of suppliers that benefits you and your suppliers.

Excessive Waste from Meetings

One of our favorite websites is despair.com. They make anti-motivation posters similar to the motivation posters that you see on office walls. A few years ago, despair.com created a poster that said, “Meetings: Because No One of Us is as Dumb as All of Us.” An extremely large majority of meetings are very wasteful. In fact, most workers attend a total of 61.8 meetings per month.6 Other studies show that half of the time in meetings is wasted.7 This equates to about 31 hours a month of unproductive time spent in meetings for the average worker. If you assume the average salary of $68,000 for the average business manager, which was taken from Indeed.com, each company likely wastes $13,175 on each and every worker a year in unproductive meetings. For a company with 100 managers, this is $1,317,500 a year wasted in unproductive meetings! This figure does not even begin to include the money lost because the worker can’t spend time on productive, money-making activities. Likely, the average company loses several million a year thanks to meetings.

![]() Note Stop the wasteful meetings! They are most likely costing you millions.

Note Stop the wasteful meetings! They are most likely costing you millions.

There are many reasons why meetings have become such a large source of waste. The first is that many people haven’t taken part in productive meetings, so they do not know how to have a productive one. We will discuss this is the following section. Another reason is that people fail to realize why they should have meetings. It’s the “this is the way we have always done things” mentality again. We literally have over 100 years, maybe even 1,000 of thinking that if you need to get something done, bring people together into a meeting and discuss it. Partly based on our history, but partly based on faulty myths. For example, many of us believe in the concept of brainstorming.

Brainstorming is a good example of a business concept that doesn’t work in actuality. In 1948, Alex Osborn, a partner in the advertising agency B.B.D.O., wrote a book called “Your Creative Power” about how he got the advertising executives at his firm to be more creative. In the book, which quickly became a best seller, Osborn talked about the concept he invented called brainstorming. Since 1948, hundreds of researchers have tried to replicate the concept. Instead of being productive, researchers have found that when people come together, fewer ideas are created and the ideas themselves are less innovative. By contrast, studies have shown that the more people involved in a project, the better the outcomes are.8 The problems is not with people coming together to share ideas. Instead, the problem is in having people sit in a room and try to work out a problem during a specified meeting time. People are better off alone. Only after everyone has a solution or an idea should groups should come together and briefly share their contributions and outline a plan of action.

![]() Note The effectiveness of brainstorming is an urban legend.

Note The effectiveness of brainstorming is an urban legend.

Since they are a necessary part of business, you should consider ways to make the meetings you do need more productive. There are some simple things that you can do to ensure that your meeting time is efficient. The first of these is to ensure that any meeting that you have has a real purpose. The scope of this includes other names for meetings such as committees or councils. Any time a group of people get together to discuss something, it is a meeting. If your meeting doesn’t have a purpose, you shouldn’t have it. An easy way to ensure that you have a purpose is to make agendas a requirement for all meetings. An agenda not only tells you what the meeting is about, but also gives you a clear timeline and some deliverable outcomes. When you insist on an agenda, you may realize that “quarterly” or “standing” meetings are not worthwhile. By agenda, we do not mean 1) Old Business, 2) New Business. We mean specific action items that need discussed. These must be issues that cannot be resolved via e-mail or through people working independently.

![]() Note If your meeting has a purpose, it should have an outcome.

Note If your meeting has a purpose, it should have an outcome.

Another core requirement for an agenda is a timeline. Meetings have a start and end time. Typically, any given meeting will last an hour. Meetings should operate on the college class schedule. That is, if the meeting is scheduled for an hour, then make it a 50-minute meeting. This not only reduces your time in the meeting by 18 percent, but it also gives you time to transition between meetings or other commitments. I once worked with an operations manager who would lock the conference room door no more than one minute after the start time of a meeting. Although this seems extreme (it is), any of you who have worked in a company that habitually runs late will appreciate this approach. This operations manager successfully changed the culture to having meetings that start and end on time over the course of a few weeks. With meetings that start and end on time and an agenda, you are more likely to get value from your meetings.

If your meetings have a purpose, there should be some decisions or actions that come from it. I have seen minutes from meetings that read like a long policy manual that nobody understands. I once heard a saying that when you write a five-page memo it is because you didn’t have time to write a one-page memo. The reason this saying is true is because it takes more effort to be brief than to be verbose. Your meeting minutes should be brief. Often, meeting minutes may not be necessary. Simple documentation of the decisions that were made or actions to be taken prior to the next meeting are often enough. The beginning of the next meeting on the same subject will be to review the actions that were to be taken and ensure that they were completed.

![]() Note Meetings should follow a specified timeline. They should also have actionable outcomes.

Note Meetings should follow a specified timeline. They should also have actionable outcomes.

The size of meetings is often a critical factor leading to their success or failure. Groups that are larger than six or eight are less likely to be productive. The challenge of structuring a team, a regular meeting, a committee, or work group is limiting the membership to the absolute minimum amount of people necessary. Think about departmental or company meetings, for instance. These types of meetings are not “meetings” because there are too many people in the room. What you end up with is one person lecturing and everyone else listening. If this is the case, the material can be typed up and sent out via e-mail or placed on the company’s intranet. Managers rarely want to admit that these types of meetings don’t have value, but they don’t.

Once your group size is established, you need to set a frequency for the meetings. For any group, the frequency depends on the work to be done. Project-based teams should meet weekly or biweekly to help maintain momentum and finish the project on time. Committees or work groups need to set frequencies that ensure that the work is timely. If a committee’s meeting schedule causes delays in other parts of the business, then the committee does not meet frequently enough. Much like the approval-process example in the Chapter 6, with lack of a decision or action from a committee, good employees will bypass the established structure to get the work done. Committees need to meet frequently enough to avoid this.

![]() Note Meetings are very frequently a waste of time. Always have an agenda, never meet about things that can be resolved via e-mail, have measurable objectives, have a maximum of eight people, and meet no more than needed.

Note Meetings are very frequently a waste of time. Always have an agenda, never meet about things that can be resolved via e-mail, have measurable objectives, have a maximum of eight people, and meet no more than needed.

Waste by Not Using Process-Improvement Techniques

The operations management for healthcare course that I teach is almost entirely based upon process-improvement techniques. One of my students asked why the course focuses on this one aspect of operations management. The answer is that much of any business program is dedicated to operations management. Another student felt that the operations management course “ties it all together.” Operations management is about managing people, resources, finances, sales, inventory, technology, and basically anything this or any other business book discusses. When you get your MBA or business degree, you are lucky if you get one class period to talk about process improvement. Of course, every function in every organization can benefit from challenging the status quo and looking for ways to improve.

The waste in process improvement is in not actively pursuing process improvement in some way. I have seen multiple companies with issues with quality and profitability make huge improvements through process-improvement methods. We will go over many of these tools in the appendix of this book. The only wastes you can have from process improvement are not doing process improvement or not finishing it. What I mean by not finishing is a phenomenon I have seen in companies where resources are spent training employees who work on projects that aren’t completed. There is often no requirement to continue improvements after the initial project. Process improvement is a company culture, not a short-term solution. It needs to be engrained into the fiber of your organization.

Leveraging Technology

While we talk a lot about technology in Chapter 6, we have a few comments to make here in regard to the operational use of technology. Over the last couple of decades, technology has improved at such a great rate that it’s hard to keep up at times. Some of the greatest opportunities for improvement that we have seen are related to technology improvements. Plastic injection molding was revolutionized by the use of pressure transducers, temperature transducers, precise electric machines, and automated process changes based on feedback from the technology. Healthcare has had great improvements in imaging technology, which has allowed doctors to give more accurate diagnoses and improved care. Wireless warehouse management systems and logistics software has made possible some of the amazing order fulfillment that is done by companies like Amazon. There is no doubt that technology continues to help companies.

The waste in leveraging technology is caused by not properly evaluating when you should use the technology. Technology should be utilized to implement necessary quality improvements, meet customer needs, or improve the bottom line. Without the need, you should seriously consider if technology improvements are necessary.

On the other hand, you should evaluate some commonly used old technology to see if it is still necessary. There are still large companies in the United States who routinely use carbon paper forms or dot matrix printers to process customer orders. Fax machines and pagers are also commonly used in healthcare even though there are more efficient options. Other than when buying a house or working with healthcare providers, I have not used a fax machine since the 1990s. If I need to send a document to someone, I scan and e-mail it. You should look at your technology use and question if you are utilizing antique technology or if the technology is just fine for what you need. Use your technology to help your operations and make them more efficient.

![]() Note Utilize the correct technology for your business.

Note Utilize the correct technology for your business.

Waste from Magical Thinking

Magical thinking in business operations is the tendency for business leaders to think that there is unlimited capacity to do work. This includes not prioritizing work. Most people can handle a few (three to four) small projects effectively. When you ask your employees to do more than a few projects without proper prioritization, you set them up for failure.

The concept of magical thinking can be expanded to other areas, such as pursing new technology, facilities, or products without first having a customer need to do so. The research associated with understanding customer needs prior to investing in these things can avoid this magical thinking waste.

Magical forecasting is forecasting higher sales without real evidence that sales will increase. Magical budgeting is thinking that your financial performance will change without making changes to your operations to actually improve performance.

Magical thinking drives many forms of waste in companies due to the wasted resources pursuing unrealistic expectations. It frustrates workers who feel that they cannot accomplish all that is asked of them. It frustrates leaders who expect improvements that never seem to happen. The solutions to magical thinking are either prioritization or asking why. Prioritize work to ensure that employees have time to get projects completed. Ask why you expect sales to increase or supply costs to decrease. The simple 5 Why Lean tool that is designed for root cause analysis also works very well for decision making. For example:

1. We expect sales to increase six percent next year.

o a. Why?

2. Walmart is going to sell more of our products.

o b. Why?

3. We lowered our prices and committed to some promotions.

o c. Why do we think consumers will buy the product from Walmart?

4. Well, ummmm…

Obviously, if you go through the five whys here, you will realize this is probably a bad decision. Some retailers return goods that did not sell well back to the manufacturer. With conflicting priorities in companies and limited resources, it is the responsibility of leaders to avoid magical thinking. Make sure you always perform a complete analysis of your decisions.

![]() Note Avoiding magical thinking will lead you to meet realistic goals.

Note Avoiding magical thinking will lead you to meet realistic goals.

Waste by Not Utilizing Your Workforce

Remember that the three major costs of operations are materials, labor, and overhead. Considerable waste also occurs when managing people. We talked about some of these in Chapter 5. We talked about the waste of not using your employees to develop improvements. You hired your employees. Now use them!

Your employees are experts because they are the people who do the work. They are not the people with the highest salaries or biggest titles. The experts are not a group of managers trying to figure out what the worker is doing wrong. Instead, the experts are the workers. No process-improvement team can hope to be transformational without the input of these experts. Without them, you are wasting your time.

Many of us have heard stories of continuous improvement goals that were never achieved. The reasons for failing continuous improvement initiatives are numerous, but one of the most prevalent reasons is because the frontline workers are not involved. Because the frontline workers are most familiar with the process, they are the ones most equipped to solve problems.

![]() Note Which method you use is not as important as having a continuous improvement method in place.

Note Which method you use is not as important as having a continuous improvement method in place.

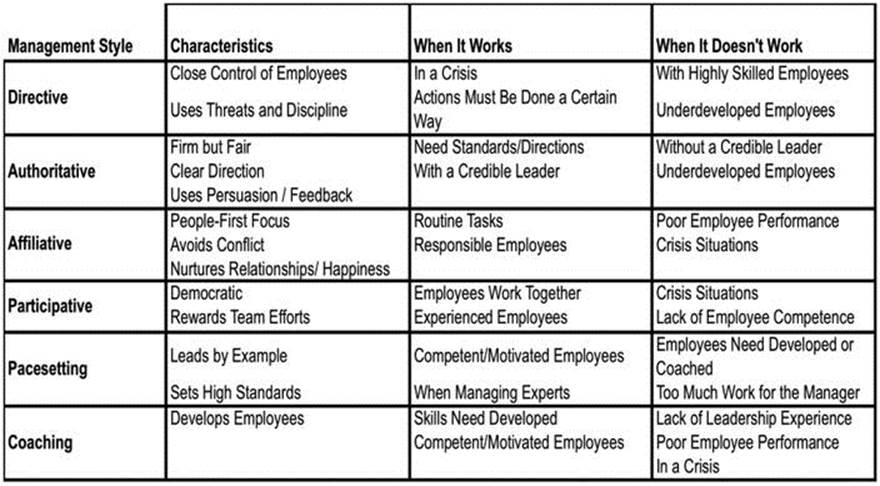

Along with these wastes, another great waste is the way you interact with employees. Leaders need to understand the needs of each individual employee. Each manager tends to have her own style of management. It is entirely wasteful to think that even a good manager is the right manager in every situation. Certain management styles are ideal for certain employee types and business situations. Figure 8-7 shows some characteristics of six management types.

Figure 8-7. Management Types (Source: Cardinal, Rosalind, “Six Management Styles and When Best to Use Them–The Leaders Tool Kit”, April 13, 2013, http://leadersinheels.com/career/6-management-styles-and-when-best-to-use-them-the-leaders-tool-kit/)

You should identify the type of manager you are and the types of managers you manage along with your employees and business situation. If the management style doesn’t align well with the current situation, you should look for ways to modify your natural management style or get a different manager to help. Once you identify your management styles, you need to either maintain a group of employees that align with your style or learn how to adapt your style based on the needs of your employees.

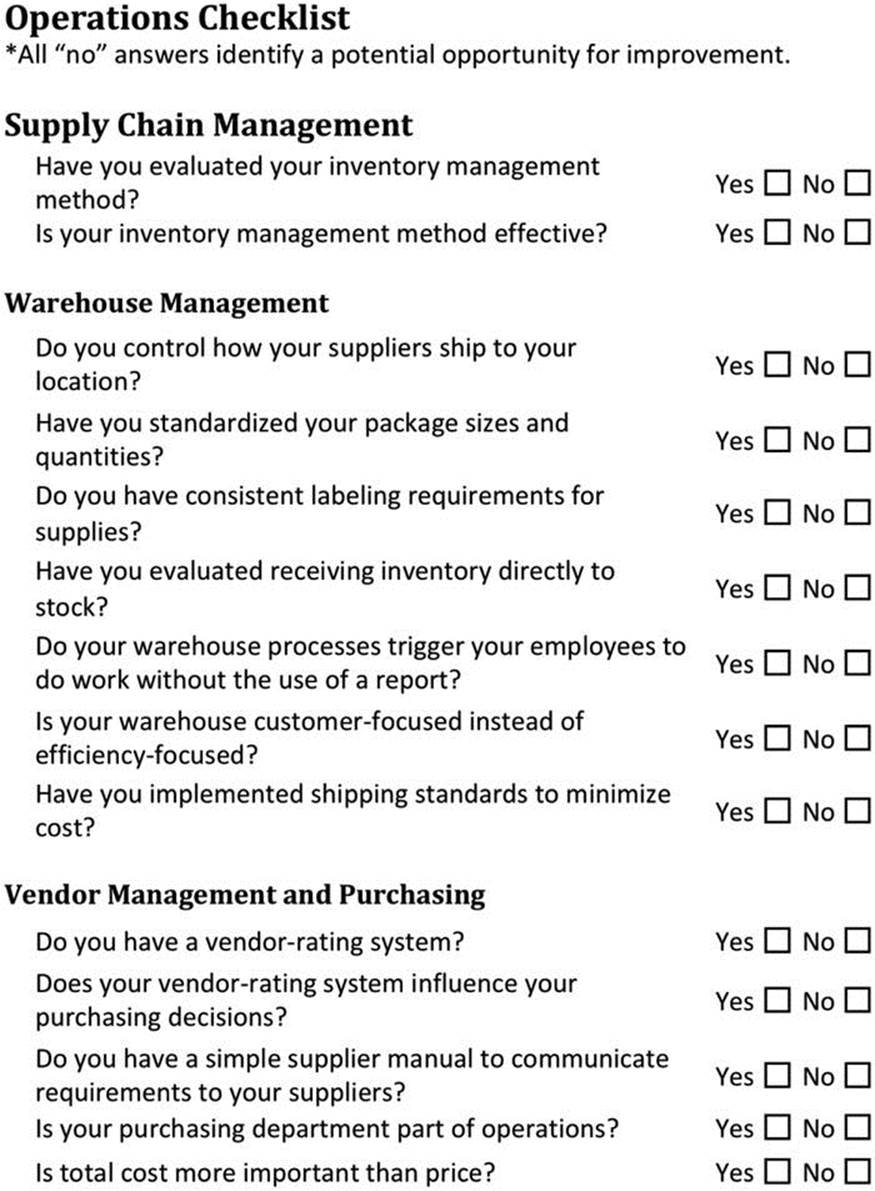

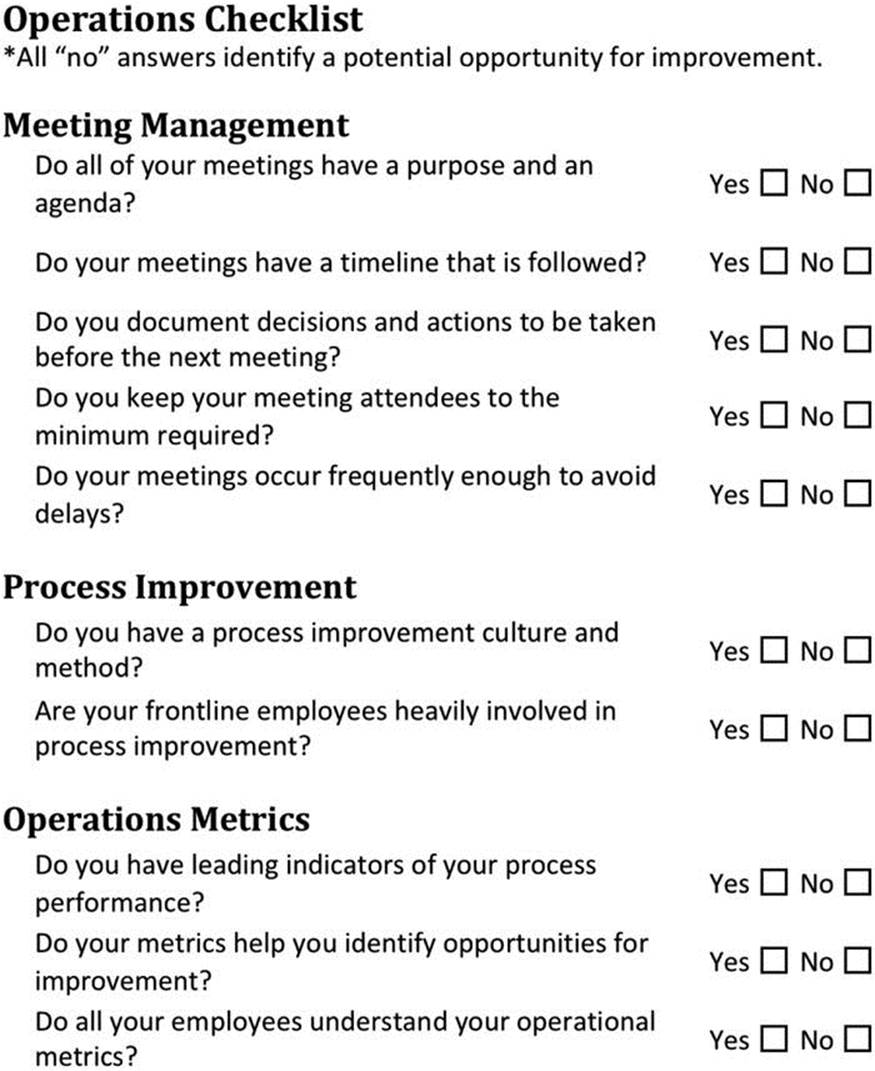

Operations Metrics

In order to improve your operations, you need to identify opportunities, make improvements, and show some evidence of the improvement after the work is done. Since all businesses need to have continuous improvement, all businesses must also have good operational metrics.

Operational metrics have many manifestations. In call center operations, the primary metrics may be minutes on the phone calls, time that customers wait to get an answer, or some kind of output metric such as sales made or problems resolved. In manufacturing you probably have some throughput metrics such as pieces per hour and some quality metrics such as percent rejected. In a restaurant you may have an upsell rate telling you the percent of alcohol and dessert sales of the total or the food and labor cost percentage of sales. In healthcare, you have length of stay, mortality rate, and readmissions metrics to tell you how well you are taking care of patients. No matter what business you are in, there are operational metrics you should be examining in addition to your financial outcomes.

Performance Management

I once worked for someone who had a few areas of focus that he was looking at in order to “turn around operations.” These included the usual suspects, such as labor, utility usage, quality, and safety. He established a bonus program where if the employees reduced the internal reject percentage and the number of safety accidents, every employee would get a semi-annual bonus. And it worked! Unfortunately, the warranty claims from external quality issues increased and employees who legitimately got injured failed to report their injuries (because rejects and injuries just weren’t reported). Any potential savings that these improvements yielded were gobbled up by the warranty issues and lack of customer satisfaction. It was also not the right thing to do.

In process improvement we look at which inputs to our process drive the performance that we are seeing. Or Y=f(X). The same is true for performance measurement. Focus needs to be on the behaviors or process metrics driving the performance that we want rather than measuring the end performance. For instance, for employee safety, improving the reporting of accidents that were avoided or potential safety issues will lead to a reduction in accidents. We should incentivize those metrics.

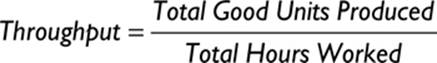

Labor Metrics

Labor metrics may vary depending on your industry, but all industries must manage labor. Your labor metrics must be based on a valid output per unit of labor. We talked about this in regard to sales productivity in Chapter 4. Sales productivity is not commonly measured because sales functions typically don’t consider the sales person’s time as variable labor that must produce an outcome. A few common metrics are applicable in most industries. The first is paid hours per unit. The unit may be a service, a sales dollar as a portion of market potential, or a product, but the basic metric is the same. You look at paid hours per unit to see how effective your labor expense is.

![]()

Worked hours per unit is a similar metric. You should look at both paid hours per unit and worked hours per unit. The difference between the two is the non-productive time that is included in your labor expense, such as training, vacation, or sick time. Worked hours per unit tells you how efficient your people are. Paid hours per unit tells you how productive your total labor expense is.

![]()